Four things to look for in a robotic integration partner

Control Engineering

APRIL 9, 2023

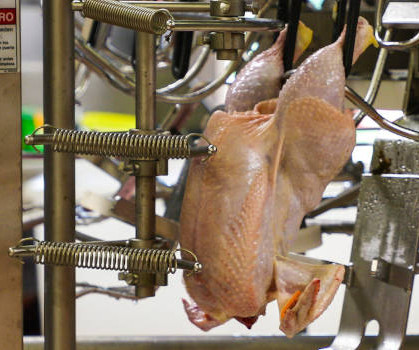

Learning Objectives As supply chains are disrupted, baby boomers age out and the need for general use products continues to grow, manufacturers are faced with producing more with less. However, bridging the gap between an unknown automation system and full robotic implementation can be an intimidating process.

Let's personalize your content