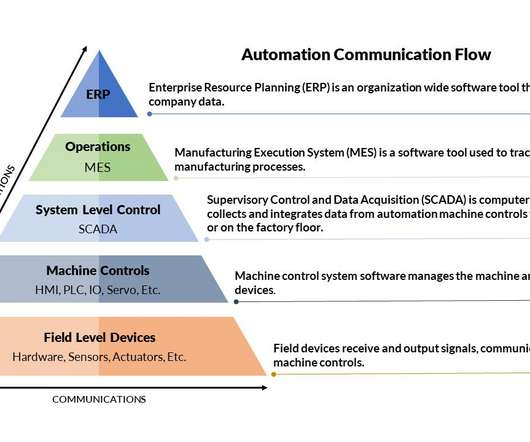

Understanding Industrial Automation in Industry 4.0

Trimantec

AUGUST 30, 2021

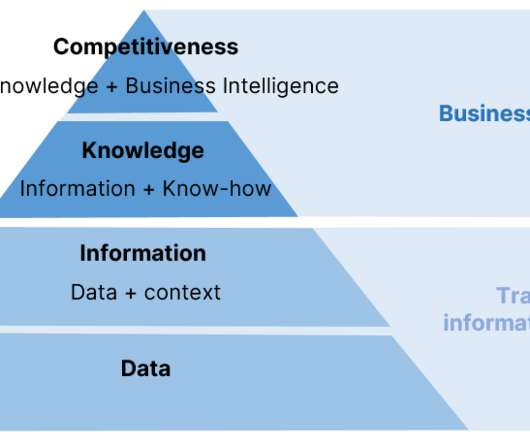

Are you excited that the future of American manufacturing is looking brighter due to reshoring? Manufacturing has changed. There are new technologies and jargon, such as talk of Industry 4.0, American manufacturers will need to play catch-up in order to continue growing and speeding re-shoring opportunities.

Let's personalize your content