Dynamic Manufacturing India May-June 2025 Edition

Dinesh Mishra

JUNE 13, 2025

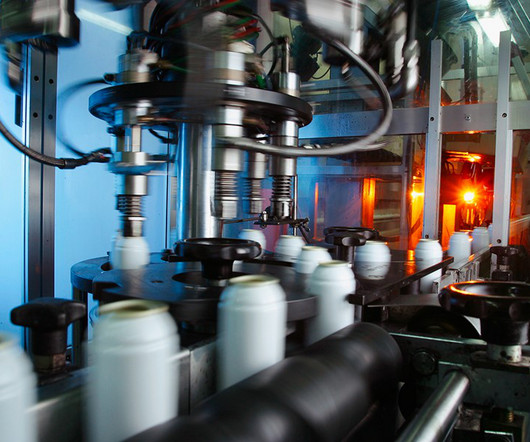

To counter this, India must invest further in technological upgradation , embrace data-driven decision-making , and uphold global quality benchmarks across manufacturing units. The industry is evolving rapidly, requiring competencies in advanced manufacturing, mechatronics, robotics, and AI-driven vehicle design.

Let's personalize your content