Unleash the power of smart manufacturing

Control Engineering

OCTOBER 10, 2022

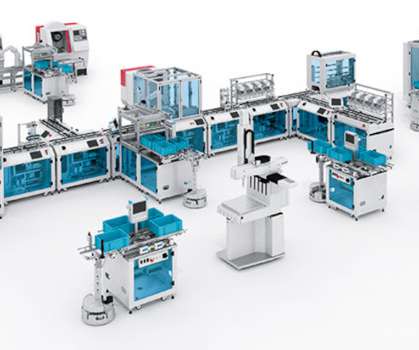

On day 2, October 18, of the Fall 2022 session of CFE Media’s Virtual Training Week, Ted Rozier, director of engineering at the Mason, OH-based Festo Didactic Solution Center, North America, will present on the topic of “ How to unleash the power of Smart Manufacturing while ensuring automation and robotic safety. ”. technology trends.

Let's personalize your content