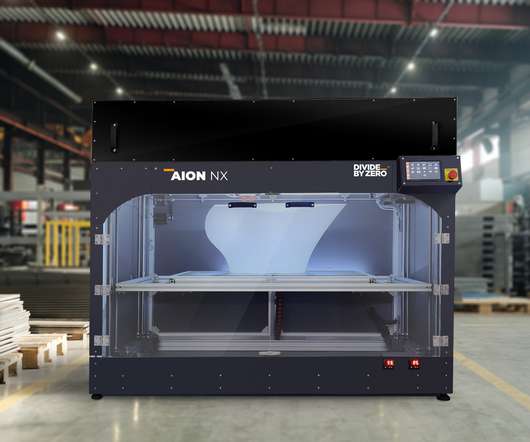

8 Ways the Plastics Industry Is Using 3D Printing

Mold Making Technology

APRIL 3, 2024

Once relegated to rapid prototyping, 3D printing technology has now advanced far beyond the design studio. Today molders, moldmakers and OEMs alike are turning to this layer-by-layer production technology to save time, serve new markets and even fill supply chain gaps. Machines have improved and material options have widened.

Let's personalize your content