Building a traceability 4.0 foundation for automation

Control Engineering

MARCH 27, 2023

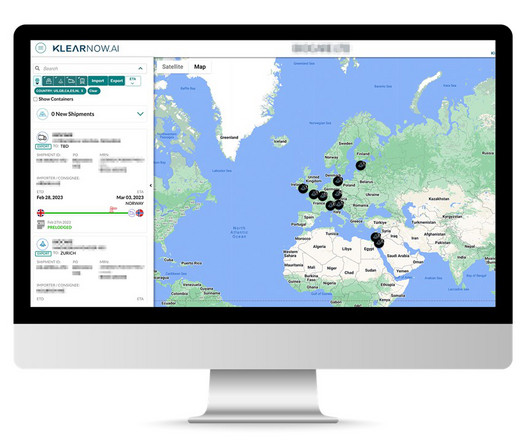

Traceability is widely used in the world of automation, and for good reason. For example, in the food and beverage industry, traceability consumes the entire supply chain from farmers to packagers and producers to retailers and consumers at the other end. foundation for automation appeared first on Control Engineering.

Let's personalize your content