Realizing Industry 4.0

Cisco Smart Manufacturing

MAY 27, 2019

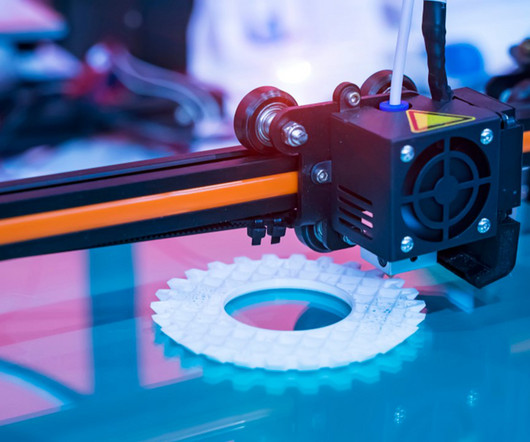

Written by Carlos Rojas, Global Industry Solutions Leader, Cisco Systems, Inc. What is Industry 4.0? As such, the world of manufacturing is betting on new technologies and data analytics to obtain “maximum optimization”; and these things neatly fall under the business strategy known as Industry 4.0.

Let's personalize your content