Bridging the Skills Gap – Formation of the IIS Indian Institute of Skills

Dinesh Mishra

JUNE 16, 2025

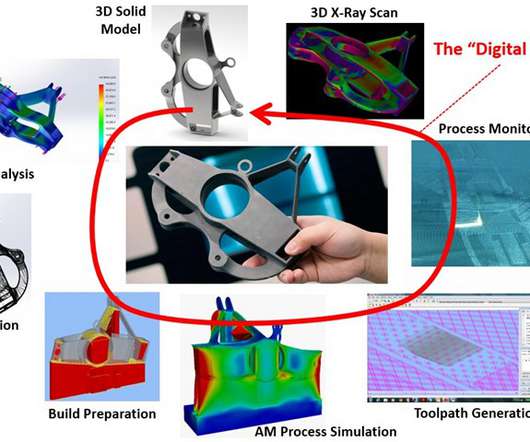

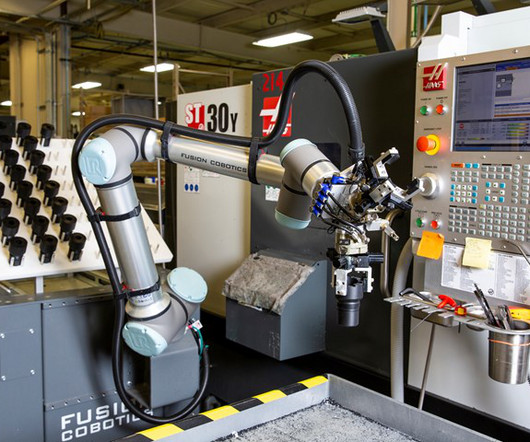

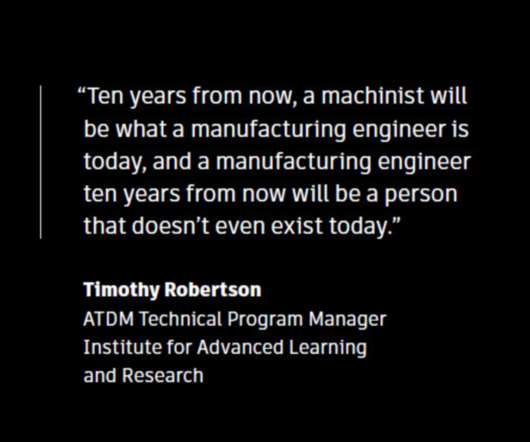

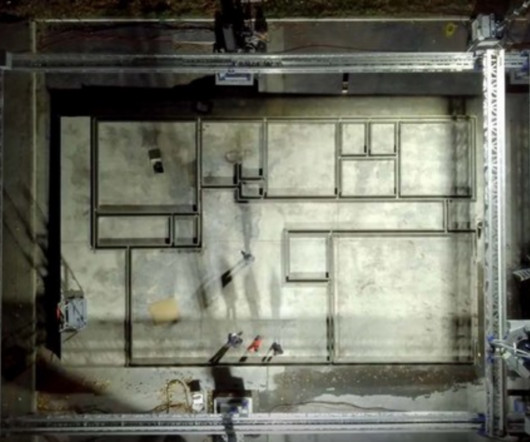

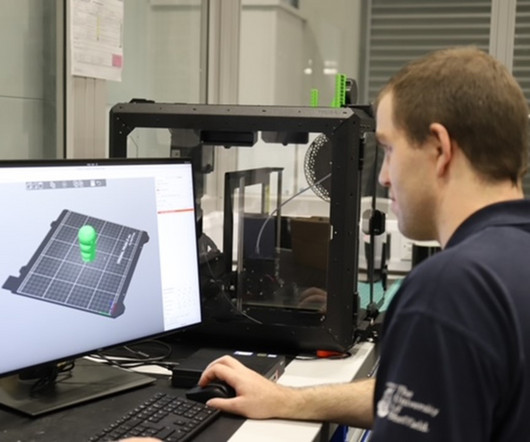

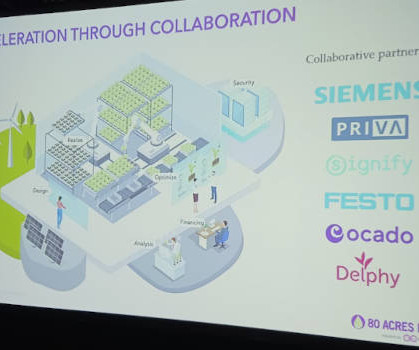

It is specifically designed to address the growing need for skilled professionals in sunrise sectors like Advanced Manufacturing & Electric vehicle. It works in close collaboration with the Ministry of Skill Development and Entrepreneurship (MSDE) and key industry leaders to ensure high-impact skilling outcomes.

Let's personalize your content