8 Ways the Plastics Industry Is Using 3D Printing

Mold Making Technology

APRIL 3, 2024

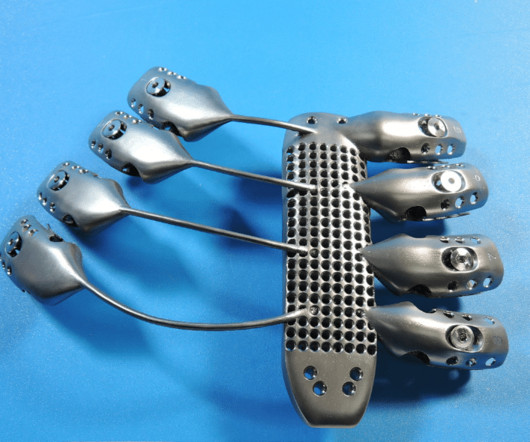

Once relegated to rapid prototyping, 3D printing technology has now advanced far beyond the design studio. 3D printing makes it possible to accelerate mold development and simplify design changes down the line. This 3D-printed EOAT incorporates air lines for vacuum and pressure into its design.

Let's personalize your content