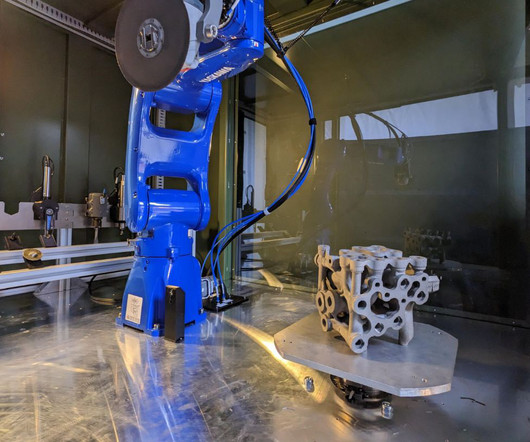

Manufacturing And 3D Printing At A Crossroads

21st Century Tech

MAY 11, 2024

If you have dabbled with 3D printing, you know it works like an inkjet printer but in three dimensions. It takes 3D digital files and renders them into physical objects by laying down ink in layers to build them. You can purchase an inexpensive home 3D printer that uses plastic filament inks. Just how big?

Let's personalize your content