Is Your Business Positioned to Capitalize on the Expanding Digital Industry Accelerators Ecosystem?

Frost & Sullivan Manufacturing

NOVEMBER 7, 2024

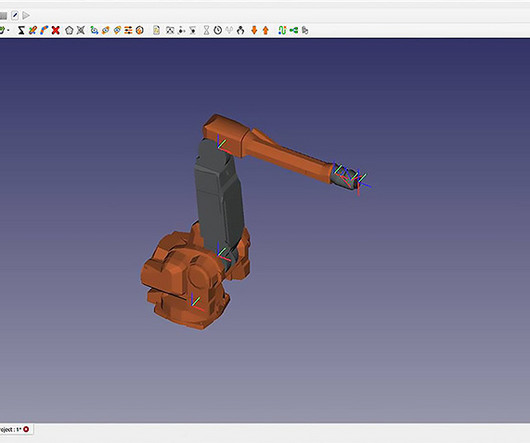

The industrial landscape is rapidly transforming, with an ecosystem of digital industry accelerators (DIAs) emerging in response to increasing demands for digital transformation in manufacturing. READ MORE: Industrial Roboverse Growth Opportunities, 2024-2029 Who Are the Power Players Driving the DIA Ecosystem?

Let's personalize your content