Pumps and Valves in the Battery Manufacturing Market, Global, 2023–2027

Frost & Sullivan Manufacturing

APRIL 21, 2025

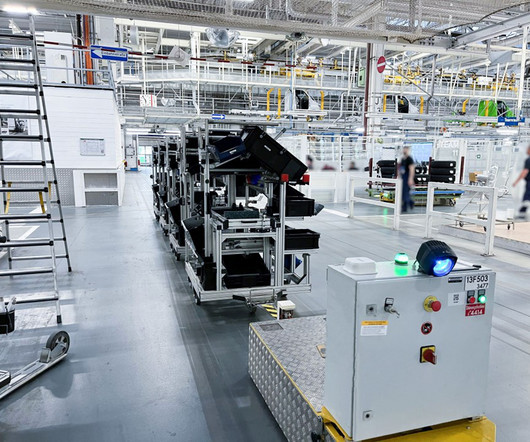

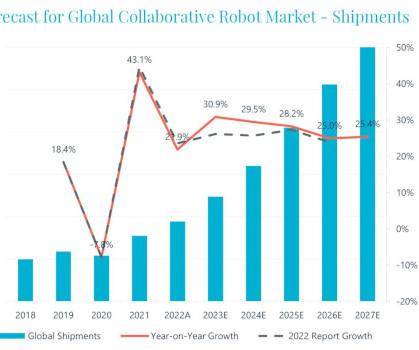

Behind the scenes, these high-growth assembly lines rely on complex fluid and gas movement systems where pumps and valves play a central role. According to Frost & Sullivan, the entire Li-ion battery value chainfrom mining to recyclingis growing at over 30% annually , with 5.2

Let's personalize your content