Automatica 2025: Wandelbots expands automation platform with NOVA Cloud

Manufacturing Tomorrow

JUNE 23, 2025

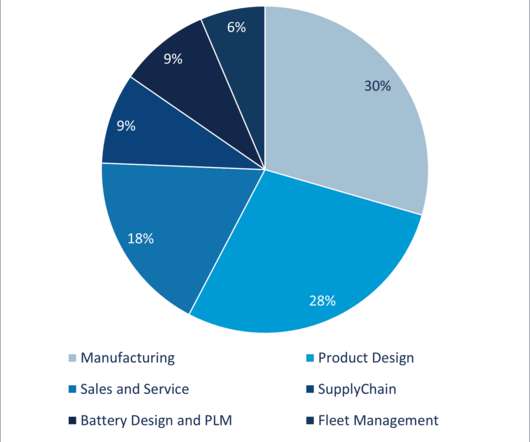

The aim of the enhancement is to provide comprehensive digital control and improvement of robot-supported processes in production and logistics cross-factory boarder. In addition to the user examples, the comprehensive Wandelbots platform and integrations with NVIDIA and Microsoft can be seen in live demonstrations.

Let's personalize your content