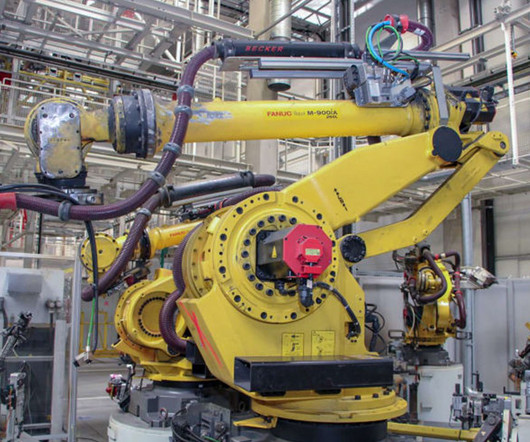

From Europe to Asia: Global Trends, Supply Chains and the Role of Used Industrial Robots

i4.0 today

OCTOBER 19, 2023

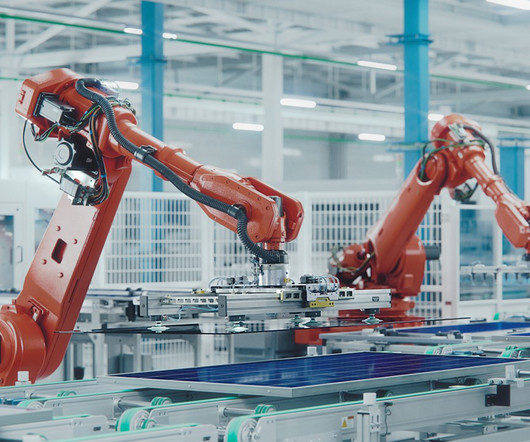

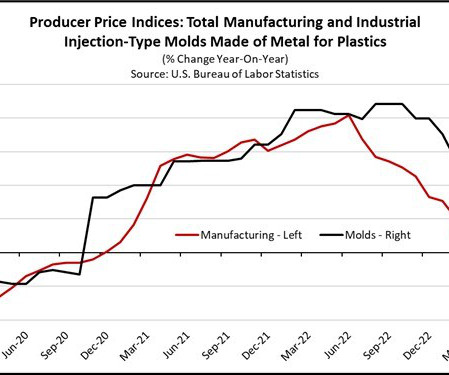

Pandemic-induced supply chain bottlenecks for established manufacturers are leading to a slow clearing of full order books – one of the reasons why Chinese robot manufacturers are in higher demand than ever before. This dynamic has led even established international manufacturers to increasingly rely on the Chinese supply chain.

Let's personalize your content