Machine vision, automation streamline logistics and warehousing operations

Control Engineering

JULY 21, 2022

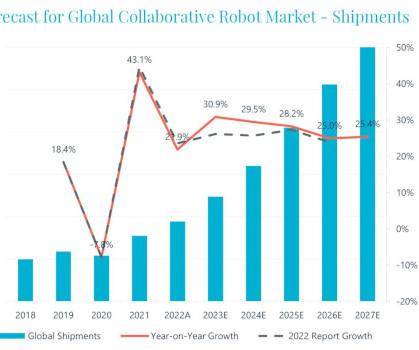

Due to staffing shortages and major supply chain issues, manufacturers are willing to emphasize automation more to meet surging demand. Autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) used machine vision and sensing technologies to move around freely and a key part around automation when it comes to logistics.

Let's personalize your content