From Trollhättan to the world: presses and machines from the SAAB factory liquidated by Surplex

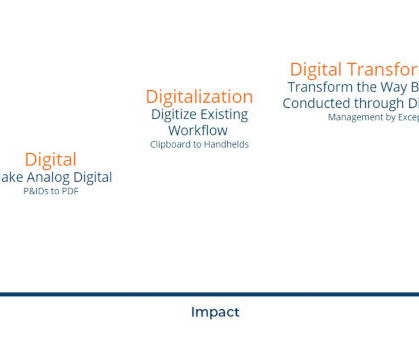

i4.0 today

DECEMBER 16, 2024

As in most industries, the automotive industry is facing the same challenges such as supply chain problems, high energy costs and the desire for greater sustainability. The most commonly used machines include robots for welding and assembly work as well as various presses.

Let's personalize your content