Matching applications to their optimal superabrasive grinding wheels can reap dividends through improved part quality and throughput, making deep knowledge of grain, bond and coating properties vital for grinding machine users. Photos courtesy of Norton | Saint-Gobain Abrasives.

Proper superabrasive wheel selection is vital to efficient grinding processes. The right wheel can optimize parts per hour, reduce tool changes, increase machine uptime, improve product quality and lower operating costs. Finding this wheel, however, requires careful consideration of superabrasive grain shape and coating, among other properties.

What Makes a Good Superabrasive Wheel?

Superabrasive wheels face aggressive grinding conditions, and must exhibit a variety of properties including hardness at elevated temperatures, high thermal conductivity to transfer heat away from the cutting edge, composition stability, wear resistance, lubricity and an ability to prevent plastic deformation.

Superabrasive wheel performance is mostly driven by the bonding matrix and the inherent characteristics and quality of the wheel’s abrasive grains, whether they are diamond or cubic boron nitride (CBN). Different grains and coatings provide different strengths, and as such are appropriate for different applications. Understanding which grains and coatings are better suited for specific applications can thus save manufacturers money over time.

Depending on the application or grinding process, a premium or higher-priced grain may be the most cost-effective option for the job. Likewise, the most expensive diamond or CBN wheel may not be the ideal choice for an application. Rather than price, it is important to focus on the shape of the superabrasive grains and the type of coating the wheel uses.

Grain Shape Determines Strength

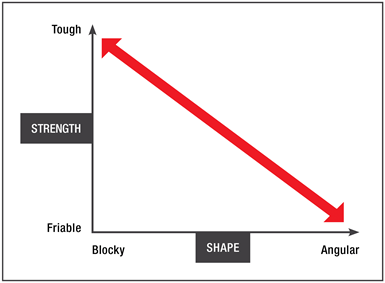

The shape of the diamond or CBN grains is a key determinant of how tough or friable the abrasive particle will act during the grinding application. Toughness refers to how the abrasive particle behaves under mechanical stress — that is, how well it resists cracking, chipping and breaking. Friability refers to the ability of the grain to break down and self-sharpen.

Tougher superabrasive grains tend to be blocky and are better at holding shape than removing material. Friable grains sharpen regularly, and their angular shape removes more material with each pass. Different applications require grains at different points on the spectrum between these two shapes.

In regards to shape, there are two polar categories: blocky and angular. The blockier or rounder the abrasive particle, the less efficient it is for stock removal, but the better it is for form holding. Blocky particles are tougher, enduring higher grinding forces before breaking.

Conversely, angular shapes are more aggressive and better able to penetrate and remove material. However, angular grains crack under lower forces.

Ideally, it is best to have a grain that balances these two shapes, staying tough but also achieving a natural breakdown to expose new, sharp cutting edges. Without the ability to break down, the grain will dull and rub the workpiece instead of cutting, causing grinding forces to spike and creating serious issues for both the wheel and the workpiece.

The Correct Coating for the Job

Coating is the process of completely and uniformly covering the superabrasive grains with a layer of additional material. This process increases the size and weight of the grain, and is usually performed to boost qualities such as strength and durability during grinding applications.

The strength with which the bond matrix retains the abrasive grains drives the effectiveness of the grinding wheel. One key benefit of coatings is that they texturize the diamond or CBN particle for better adherence to the bond of the wheel, whether that wheel is resin, vitrified, metal, a hybrid material or something else. The improvement in mechanical and chemical retention to the bond system fortifies wheel integrity.

If a shop plays its cards right, the cost savings and maximized throughput from choosing the right grinding wheel can easily become a competitive edge.

Nickel, copper and silver coatings are the most common superabrasive coatings. Nickel coatings are common in resinoid-bonded wheels. These coatings improve wheel life, surface finishes, heat dissipation properties and mechanical adherence to the bond matrix to maximize productivity.

Copper coatings are the coating of choice for dry grinding applications due to copper’s aptitude for transferring heat away from the grind zone and its enhancement of mechanical and chemical grain retention to the bond system.

Silver coatings are more expensive, but showcase the highest thermal conductivity of these three coating types, as well as improved grain retention and additional lubricity. Silver is the coating of choice when using straight oil as a coolant.

The amount of coating on the abrasive grains can range from 30% to 70% of the total weight of the coated grain. Coatings on diamond grains are typically between 50% and 56% of the total weight, while CBN grains tend to devote up to 60% of the total weight to coatings. Coated superabrasives are generally more expensive than uncoated abrasives due to their higher expected performance and the extra manufacturing steps required for their production.

Even microscopic abrasive tweaks in a grinding wheel can become a game changer for grinding systems and processes. If a shop plays its cards right, the cost savings and throughput increase from choosing the right grinding wheel can easily become a competitive edge.

Related Content

How to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

Read MoreThreading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read MoreVolumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

Read MoreGrinding Wheel Safety: Respect The Maximum Speed

One potential source of serious injury in grinding comes from an oversight that is easy to make: operating the wheel in an over-speed condition.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)