When the fiber laser beam contacts the surface, it interacts with the coating on the mold — but not the mold itself — and then cleans the mold surface by transforming the coating into vapor or dust that then flakes off. Photo Credit: Rocklin Mfg.

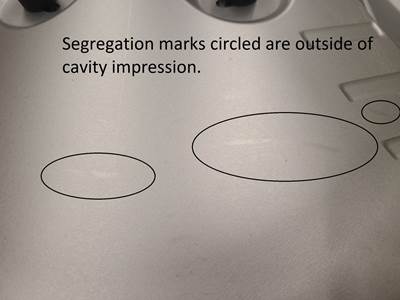

When a mold is contaminated with rust, dirt, grease, oil or other substances, it can damage the injection molding process and harm the quality of the molded products. These contaminants can cause surface defects that are then transferred to the molded parts, produce increased mold corrosion, and trigger heightened wear and tear on mold surfaces.

The mold release process could also be impeded as grease and oil make it difficult for the molded part to separate from the mold, causing lengthy cycle times and damage to the part during ejection. In short, dirty mold surfaces can result in costly damage and downtime.

Fiber laser cleaning is a fast, precise and reliable mold cleaning method. Now, with the option of full portability, it can be accomplished more efficiently than ever before.

There are a wide range of mold cleaning alternatives available, each with its pros and cons. Chemical cleaning can remove contaminants, but it can also damage certain mold finishes. Ultrasonic cleaning and baking soda blasting can be effective methods on certain molds, but they can cause damage to others and result in surface wear. Steam cleaning can break down and remove some oils and greases, but it may not be suitable for temperature-sensitive molds.

How it Works

Portable laser cleaner weighing 50-60 pounds.

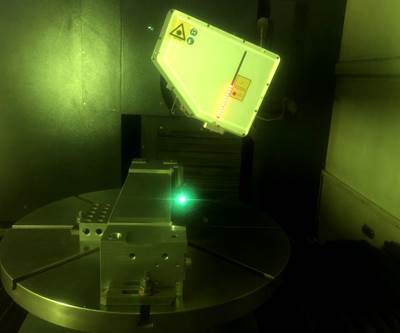

Fiber lasers offer a simple, fast and precise alternative that minimizes these mold cleaning risks. When the fiber laser beam contacts the surface, it interacts with the coating on the mold — but not the mold itself — and then cleans the mold surface by transforming the coating into vapor or dust that then flakes off.

This can be done very quickly, and with an all-in-one, portable laser cleaner weighing just 50-60 pounds, enabling the user to bring the system directly to the mold for even greater productivity.

Key Laser Features and Functions

The laser can be precisely controlled, allowing for selective cleaning of specific areas on the mold, which can be a critical feature for intricate molds. Laser cleaning is a noncontact process, eliminating the risk of wear and tear associated with abrasive cleaning methods. It’s also a dry process that doesn’t require the use of consumables or chemicals that can carry a host of environmental and safety risks.

The laser’s low heat generation avoids thermal damage to molds with temperature sensitivities, and the power can be adjusted based on the contaminant type. Also, there is no residue left behind, ensuring that the mold is cleaned without contaminants remaining after the cleaning is completed. Along with extending the life of molds by alleviating wear and tear in the cleaning process, the fiber laser source can be used for up to 100,000 hours with minimal maintenance required.

Fiber laser cleaning is a fast, precise and reliable mold cleaning method. Now, with the option of full portability, it can be accomplished more efficiently than ever before.

Related Content

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MorePortable Low-Heat, Non-Arcing Resistance Welder for Mold Repair

Rocklin’s user-friendly MoldMender Micro Welder delivers simple and cost-effective localized repair in-house with precision and versatility, enhancing mold and die durability and reducing disassembly and downtime.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreRead Next

Laser Welding Repairs Micro-Threaded Inserts Fast

Moldmaker/molder Medbio LLC sent unscrewing cores with damaged micro-threads out for repair via laser welding and polishing, slashing nine weeks off lead time to produce new inserts.

Read MoreHow to Eliminate Streaks and Weld Problems with Laser Technology

Laser technology overcomes streaking and welding challenges for new mold textures and texture repair.

Read MoreThe Advantages of Digital Laser Technology for Mold Texturing

Understanding the nuances and benefits of laser ablation and when to use it.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)