One-Stop Shop Simplifies Custom Surface Textures, Mold Performance

NPE2024: Standex Engraving Mold-Tech specializes in managing every step of the project process, from texture design and engraving to preparing the tool for production.

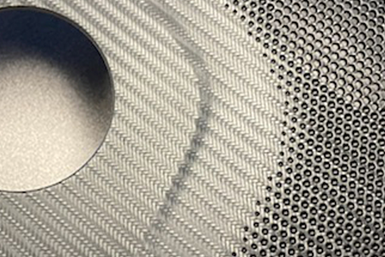

Texturing performed on a front car door speaker grill. Source | Standex Engraving Mold-Tech

Through its One Partner Solution, Standex Engraving Mold-Tech offers services and technologies that support projects from the beginning to end — from specialized finishing through to manufacturing support.

The company’s services start by designing a custom texture tailored to a customer product, verifying those grains on the product, engraving the tool and then optimizing that tool for streamlined manufacturing. Standex Engraving Mold-Tech highlights the seventh-generation Ford Mustang as a key example of its capabilities, demonstrating its laser engraving technology throughout, but in particular on the front door speaker grill (shown at right), which presented a challenge.

Ford’s front door upper speaker mold was laser engraved with a carbon fiber texture onto a steel surface consisting of both benched and EDM in a seamless fashion. Standex Engraving notes the preciseness of laser engraving, which can control the grain locations around featured surfaces and shut-offs. The end result camouflages the speaker holes within the texture itself, eliminating the need for framing or a separate grill piece required.

Related Content

-

Use AI, Machine Learning to Take Variability Out of Manufacturing

Variability has always created insurmountable challenges for manufacturers. However, in the last decade, impact has been more painful due to a lack of experienced workforce. By leveraging technological advancements, particularly in AI, manufacturers can gain a transformative competitive advantage in both cost reduction and workforce development.

-

Plastic Injection Molder Debuts EOAT, Mold Monitoring Solutions

NPE2024: Exhibiting for the first time, European-based Mouldpro ApS highlights new solutions — the Roborex and Flosense — alongside partner Globeius.

-

Dynamic Tool Corp. Wins MoldMaking Technology’s 2024 Leadtime Leader Award

Dynamic Tool Corp., a provider of engineered tooling solutions based in Menomonee, Wisconsin, has been awarded MoldMaking Technology’s prestigious 2024 Leadtime Leader Award. The announcement was made during a live awards ceremony at the Plastics Technology booth, where owners Steve and Ken Eberle accepted the award on behalf of their team.