Mold Builder Invests in Five-Axis Milling to Open the Envelope

NPE2024: Mold-Tech Inc., dedicated to complete quality and support, continues to add to its hard milling equipment department with the Makino D200Z, enhancing mold lead times, accuracy and efficiency.

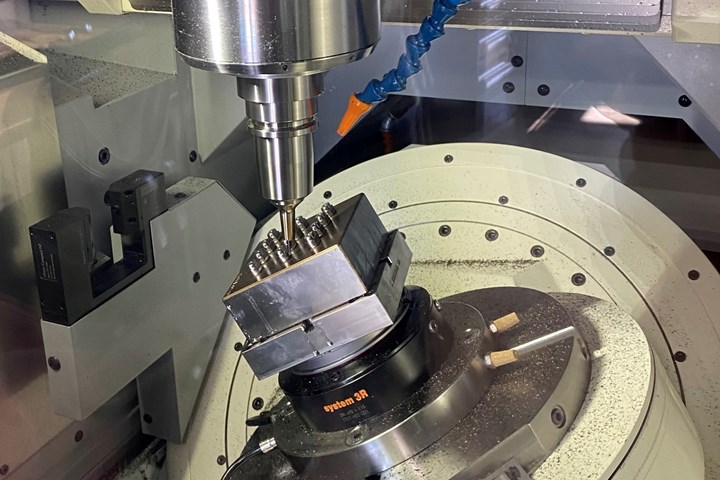

Part of the mold building process used by Mold-Tech Inc., serving the designing, building and sampling of high-quality injection molds, includes the addition of a Makino D200Z five-axis machine to its hard milling department. The company says that five-axis milling opens the envelope to options not always possible with more traditional three-axis machining, equipping its moldmaking professionals for efficiency to meet customer needs.

Five-axis milling provides many benefits to Mold-Tech’s products. Cutter reach capability and cutter protrusion length are noteworthy. Moreover, when milling with the five-axis machine, rotating and tipping the working piece allows the operator to cut on the side of the cutter radius — rather than the centermost part of the tip, which is smaller in diameter. The company says that five-axis machining also reduces the need to set up work pieces multiple times when working on more than one surface.

Mold-Tech claims that milling with the larger portion of the radial ball end mill increases cutter life and improves quality, size and surface finish of an end product; that reduced cutter protrusion from the collet adds to the improved performance of surface finish and accuracy; that a five-axis can enable more complex geometries; and ultimately, delivers faster production speed (enhanced lead times).

Related Content

-

Localized Mold Temperature Control Reduces Knit Lines, Optimizes Melt Flow

NPE2024: Dynamic localized mold temperature control Heat-Inject Technology by Incoe Corp. demonstrates how the part surface quality and the filling of the cavity is optimized with relatively little effort using targeted heat pulses.

-

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

-

Stack Mold System Combines Fast Injection With High Process Repeatability

NPE2024: Primarily designed for thin-wall packaging applications, the patent-pending mold design by Oerlikon HRSflow brings consistency, simplified maintenance and assembly and a sustainable materials focus.

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)