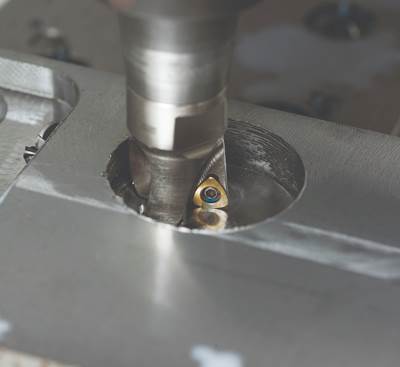

With the two-edge concept, machining against a corner or wall will not impact the next edge or leading corner, giving an equal performance per edge. Photo Credit, all images: Sandvik Coromant

PwC’s “Industrial Manufacturing” report states, “The only constant in today’s industrial manufacturing environment is disruption.” Disruptions to supply chains and productivity caused by the pandemic have driven manufacturers to diversify to new markets in order to survive. This creates an increased need for error-free precision machining.

“To stay competitive,” continues PwC’s report, “organizations must be able to integrate new business models and technologies to accelerate and adapt.” For mold builders, adapting includes diversifying product offerings and being ready to satisfy customer demand in new markets.

Mold builders are also under pressure to diagnose and eliminate product defects through error-proofing. This is a growing challenge because diversifying into new sectors means handling workpieces made from a broader range of materials like aluminum and heat-resistant super alloys (HRSAs). Also, the hardness values of these materials differ enormously from one end of the spectrum to the other. As a result, processes and machining conditions will also vary widely from part to part. They include everything from roughing to finishing on out-of-round or near-net shape cast or forged parts.

Certain types of machining also present unique challenges. For instance, when a cutting tool with a long overhang is used to mill deep, narrow pockets, the whole setup becomes unstable. This can lead to unpredictable machining and a higher risk of vibrations that, as we’ll explore, can cause cutting tool failures and downtime.

Mold builders need cutting tool solutions that provide secure and predictable machining with increased metal removal rates and reduced cycle times. Fortunately, a solution does exist. But, as PwC’s “Industrial Manufacturing” report puts it, “with disruption comes the opportunity to innovate.”

The single-sided, two-edged positive insert has a strong curved edge with a reinforced corner radius, ensuring secure and reliable machining against shoulders and corners in pocketing.

Bad Vibrations

Why are these innovations necessary? First, a machinist must overcome machining vibrations, which negatively affect performance in various ways, including displacement of the cutting tool and imperfections in workpieces. They can even cause cutter breakage and unplanned downtime. Vibrations also impact chip formation and removal, which are the fundamental occurrences inseparably involved with machining that damage the effectiveness of cutting tools.

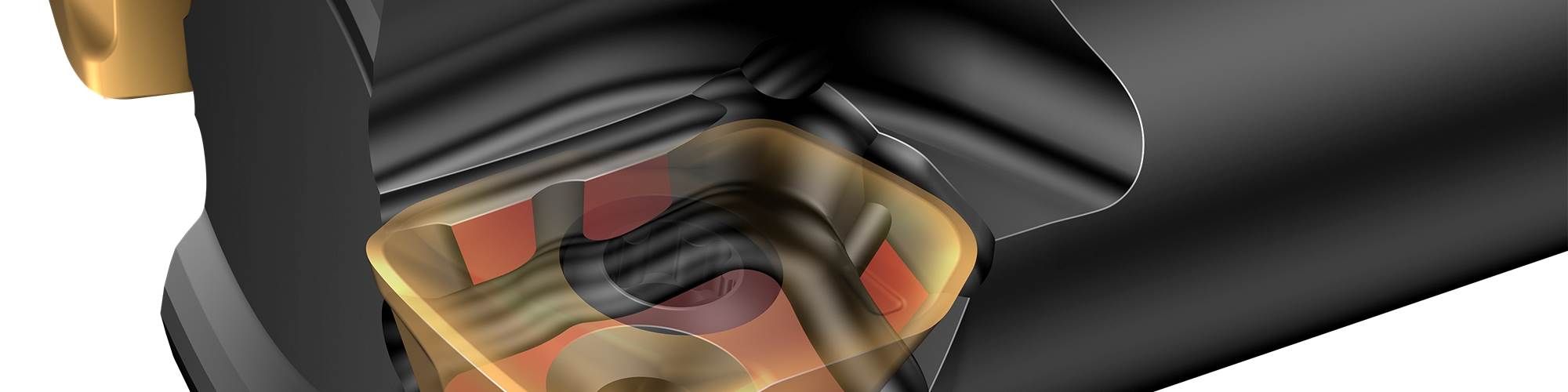

Another factor in milling tool underperformance is that most inserts have four edges. The reason for having four edges is that when one edge becomes dulled or chipped, it’s easy to rotate or replace the tip. However, the insert’s corners, between the flat edges, are its weakest. In addition, these radial edges are designed differently from the insert’s flat edges. As a result, they are often placed in the cutting zone and, as a consequence, frequently break first.

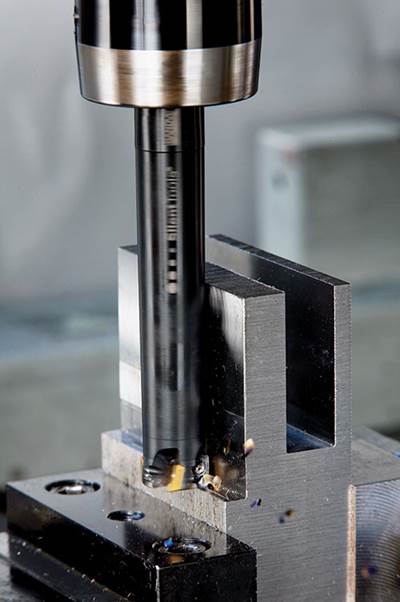

The design of this high-feed milling cutter includes a new cutter body material used for the cylindrical shank bodies, which gives levels of stiffness not seen before in this type of cutting tool.

These are the issues today’s leading cutting tool specialists keep in mind while designing a next-generation tool that would meet the stringent requirements of various sectors. Crucially, the invention needed to reduce the number of tools, changeovers and tool handling required during manufacturing for reduced cycle times and improved manufacturing economics.

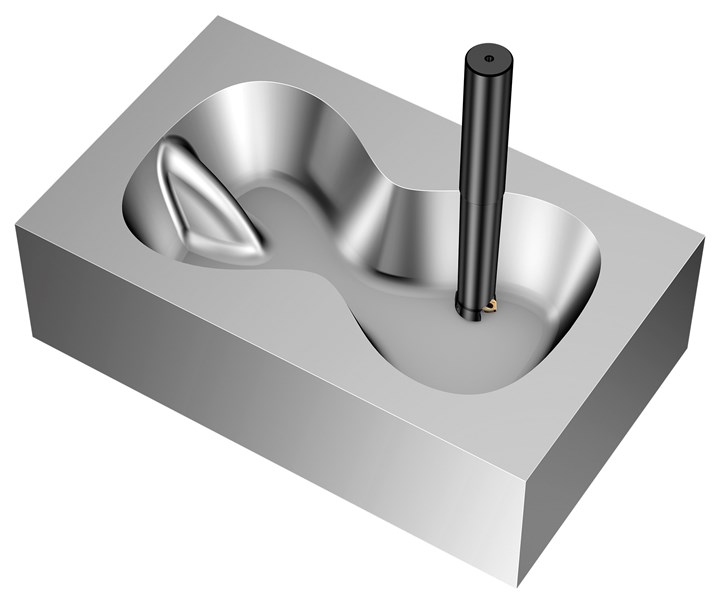

The result is a new, high-feed milling cutter designed for milling cavities, or pockets, in ISO S, M and P materials.

Innovation Opportunities

The design of this high-feed milling cutter includes a new cutter body material used for the cylindrical shank bodies, which gives levels of stiffness not seen before in this type of cutting tool. In addition, the material minimizes wear and tear during machining and reduces chip rubbing and coining — when high stress caused by high cutting forces causes plastic deformation on the insert seat. With this feature, the tip seat remains secure and undeformed, providing better tool life.

The open pocket design helps to improve chip evacuation and reduces recutting of chips. The design is optimized for chips generated by a high-feed tool and minimizes smearing of chips, especially in ISO S applications.

Next, it has a two-edged insert. With the two-edge concept, machining against a corner or wall will not impact the next edge or leading corner, giving an equal performance per edge. The advantages are greater reliability and protection against wear. The edge line of the insert’s leading cutting edge and corner radius are also optimized for further process security.

Another area of innovation is the insert cutting-edge geometry. Dedicated insert geometries for different ISO areas deliver greater optimized process security and productivity. Here, a sloped edge design delivers a gradual and light-cutting action, requiring less power consumption suited to smaller machines.

Customers have reported improved tool life over previous-generation cutters — up to 30% in some cases, although this performance will always differ depending on the material.

Precision Machining

For example, a Canadian mold and die shop upgraded its existing cutting tooling setup from one suffering from vibrations, resulting in an unpredictable and insecure machining process. To resolve these issues, the shop switched to this new high-feed milling cutter to test its performance against its existing tool. Both tools were used to perform rough pocketing on a workpiece made from H13, a popular chromium hot-work steel known for its high toughness and fatigue resistance, to produce a mold.

Each milling tool measured 25.4 millimeters (1 inch) and was run at a cutting speed (vc) of 168 meters/minute (550 surface feet/minute). In addition, the new high-feed milling cutter was run at a slightly higher feed rate with two inserts, which enabled the cut depth to be increased by 35%. The parameters were: a feed per tooth (fz) of 1 millimeter/tooth (0.04 inch/tooth), feed speed (vf) of 5,080 millimeters/minute (200 inches/minute) and axial depth of cut (ap) of 0.8 millimeter (0.031 inch).

The competing tool was run at an fz of 0.63 millimeter/tooth (0.025 inch/tooth), vf of 4,572 millimeters/minute (180 inches/millimeter) and ap of 0.5 millimeter (0.020 inch). Both tools were run until they showed signs of flank wear.

The design of this high-feed milling cutter includes a new cutter body material used for the cylindrical shank bodies, which gives levels of stiffness not seen before in this type of cutting tool.

Despite the higher cutting parameters, the new high-feed milling cutter finished a complete component with no indexing and a superior surface finish. It exhibited a 50% tool life increase by running for 300 minutes, with a 50% cycle time reduction. The competing tool ran for half the amount of time at 150 minutes. It also required additional indexing because of poor cutter life, which increased cycle times. In addition, the competitor’s insert again suffered from vibrations that caused screws to back out during machining.

The customer improved cutting tool life and more secure, vibration-free machining processes by upgrading to a new high-feed milling cutter. Even if, as PwC observes, disruption is the only constant in today’s industrial manufacturing environment, new tooling innovations support improved tool life and process security. This greatly benefits manufacturers’ competitiveness.

Read Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreIncrease Process Security and Minimize Risk

Staying competitive in the growing automotive market comes down to quality, productivity and cost per component, and all three can be accomplished with the right set of tooling solutions.

Read More

_300x250 1.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)