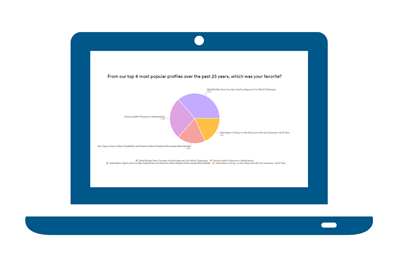

Photo credit from top left, clockwise: StackTeck Systems, Accede Mold & Tool, B A Die Mold and Cavalier Tool & Manufacturing

Mold builders are the people and businesses that make the moldmaking industry go round. Better put by Crescent Industries, “Tool and die-makers are expert workers or precisely put, artisans of a manufacturing unit.” As such, each business provides its customers with a unique range of in-house services and capabilities to meet specific demands and requirements in a variety of end markets. In this latest tech roundup, MMT features just a few of those mold builders whose work continues to make waves in the industry.

To check out tech roundups from months prior, please browse the “New Tech” section of the MoldMaking Technology website, or look up “Technology Roundup” in the homepage’s Search bar. For more information on a product featured below, click on the title link for the respective product.

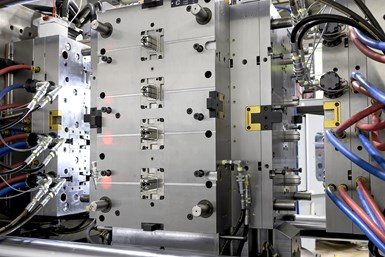

Injection Mold Builder Meets Customer Challenges Via Complex, Precision State-of-the-Art Moldmaking

Photo Credit: Accede Mold & Tool Co. Inc.

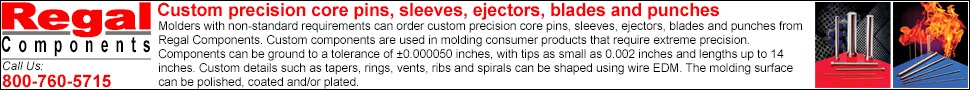

Accede Mold & Tool Co. Inc. is an independent and privately owned injection mold builder in Rochester, New York that is ITAR-registered and ISO9001:2015-certified. Accede goes beyond traditional mold building, specializing in complex and precision state-of-the-art moldmaking for the medical, consumer packaging, industrial, automotive and defense industries. The company leverages its knowledge gained from more than 40 years of cross-industry experience to develop value-added solutions that meet its customer’s most demanding challenges — from research and development pilot tooling through full turnkey system integrations.

Michigan Shop Provides Solutions for Moldmaking and Beyond

Photo Credit: Best Tool & Engineering

Best Tool & Engineering is a plastics processor that supports its customers with multiple services, including product development and design improvement for manufacturability, moldmaking, injection molding, plastic vibration welding, plastic hot plate welding and assembly for the medical, electronics and consumer durable goods markets.

Mold building includes prototype and production (low volume to high volume). Primary metals include aluminum and tool steel. Best Tool’s aluminum molds are guaranteed for 250,000 cycles with non-filled materials. In-house wire EDM for tight tolerance and precision mold building are additional capabilities.

Read Next

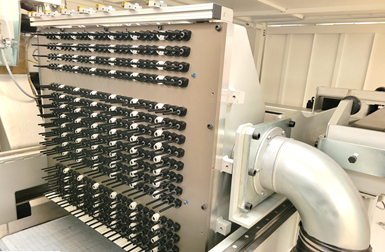

Connecting to the MMT Audience Through Polls

MoldMaking Technology understands the importance of getting to know our audience. This year, we have decided to run bi-weekly polls in our MMT Today newsletter to get to know our audience better.

Read MoreMaintaining a Competitive Edge: EDM, Automation and Machining Technology Roundup

This month’s technology roundup features products, processes and services relating to EDM, automation and machining. For example, jig grinding for large molds, scheduling automation software, cobot integration, die sinker EDM and much more.

Read MoreMetalworking Commodities for Your Next-Gen Molds

Featured in this month's technology roundup are products, processes and services that revolve around metalworking. Also highlighted is software, automation and more.

Read More