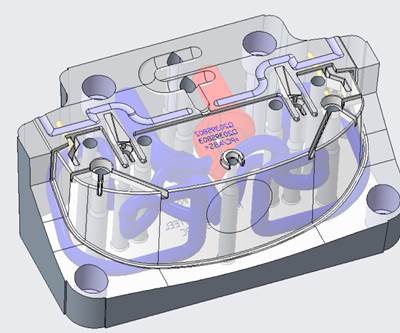

A toolroom has a variety of tried-and-true equipment, but not all machines are the right choice for a workpiece. Assessing a part’s attributes and production timeline can help determine the best machine for the job, resulting in an efficient and effective toolroom. Photo Credit: EVCO Plastics

Today’s modern toolroom includes multiple options to improve the workflow and manufacture of parts for customers. A toolroom can harness two go-to options: a CNC machine and a 3D printer. A CNC machine is the front runner for cutting intricate, specialized parts with tight tolerances. However, when parts don’t require adherence to such precision, offloading them to a 3D printer can enable a toolroom to work more efficiently and quickly. Sometimes the decision is evident when faced with whether a part should be printed or cut, but these five factors can help decide if there’s ever any doubt:

- Application: Consider the end goal of your part and the processes that will make for a more robust, higher-quality part. Those two variables can be a signal to move beyond a secondary machining operation and into an additive manufacturing technology space. One example is whether a part would benefit from conformal cooling, which can improve part flatness, sink and CPK values. Creating intricate channels and tooling inserts in the mold is best served by a different 3D printing process called direct metal laser sintering (DMLS). However, because of the complexity conformal cooling requires, traditional CNC applications aren’t able to create and position the cooling channels seen in 3D metal printing.

- Time: A hallmark attribute of a 3D printer is that it can print parts quickly. If the part needed is compatible with 3D printing operations and the printer is available, it can be programmed and run primarily unattended. While you can’t completely “set it and forget it,” for the most part you can, since 3D printers can run around the clock with minimal human interaction. Of course, the need to remove the completed parts, swap out plates and facilitate the next run keeps the process from being an actual lights-out operation. Still, users can allocate their time to more high-touch projects in the toolroom, even with the occasional printer project management.

- Nimbleness: If you’re still in the design phase, perfecting a part’s final specifications often requires multiple iterations. In that case, changing design direction quickly is made much easier with a 3D-printed part. In addition, if you need to add or delete detail, it can be reprinted until it’s perfect, shaving days off the total design and production time.

- Cost: Cost per part is always top of mind. From a financial perspective, producing a part out of high-quality carbon fiber creates end-use parts that are functional and cost-effective. For example, a roll of 3D printer material comes out to pennies on the dollar per part because it isn’t machined out of steel or aluminum — traditionally expensive materials, but even more so now.

- Accuracy: When tight tolerances matter, you likely need the accuracy of a machined part. Depending on what you’re working on and the resolution needed, a CNC machine will give the extra precision needed. Typically, a CNC machine will be accurate down to ± 0.0005 inch, while a 3D-printed part’s accuracy lies around ± 0.005 inch. That measurement doesn’t seem like a lot, but it can make a huge difference in certain end-use situations.

Related Content

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

Conformal Cooling: Not Just Faster Parts but Better Parts

EVCO Plastics has been offering DMLS conformal-cooled inserts for years and like many shops today, they outsource this work to mold builders who have expertise in DMLS.

Read MoreHow to Ensure Quality Offshore Tooling

When working with a foreign mold builder provide clear expectations and conduct comprehensive reviews throughout the moldmaking process to ensure a robust mold.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.png;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)