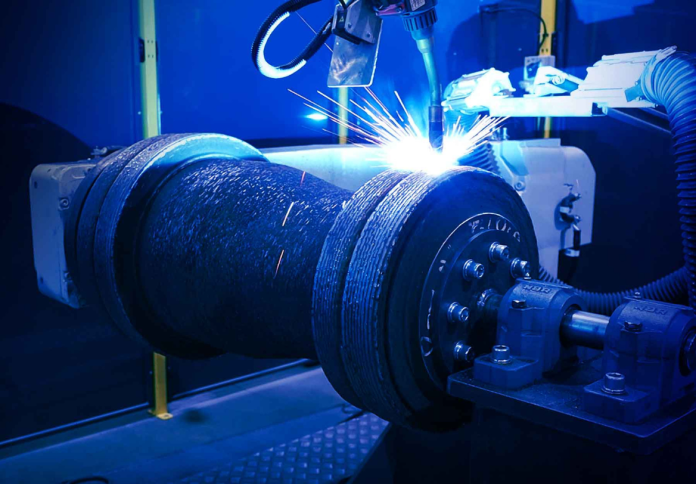

Wire additive manufacturing company AML3D is expanding the scope of its 3D printed components supply for Boeing to further develop its strategic partnership with the aerospace company.

Boeing amended its July 2022 purchase contract with AML3D to include the next phase of Aluminium test parts in the form of prototype components, increasing the value of the agreement by an additional 150 per cent.

The new purchase agreement is on standard commercial terms.

The contract expansion comes after an initial contract with Boeing in June 2021 to supply a 3D printed tooling component, which was followed by a second contract for $140,000 for structural aluminium test parts in July 2022.

“This expanded purchase contract with Boeing demonstrates the growing momentum in our commercial relationship with one of the world’s largest aerospace companies. AML3D has already demonstrated to Boeing that our proprietary WAM 3D metal printing technology produces high-quality parts on time and to specification,” said Andrew Sales, managing director of AML3D.

The ASX-listed additive manufacturing company said the latest contract adds additional momentum to its strategic push into the aerospace and defence sectors. The supply of the next phase of test parts and structural components represents continued progress toward additional, more extensive programs in the future, the company added.

“The expanded purchase contract is strategically important as it moves AML3D towards being embedded into Boeing’s supply chain, which aligns with the delivery of our growth targets for the Aerospace sector,” said Sales.

AML3D’s expansion into the aerospace defence sectors is underpinned by progress towards the implementation of the Aerospace Quality Management System, AS9100D:2016 accreditation.