September 2023 Metrology News Magazine

Editors Message:

Manufacturing industry is constantly evolving, driven by technological advancements. Over the next decade, several key technologies are expected to have a significant impact on manufacturing. One way of becoming familiar with how these advanced technologies are being embraced by equipment suppliers is at trade shows. The recent EMO exhibition, held this year in Hanover Germany, showcased many of the emerging technologies that will have a huge influence on manufacturing over the coming years including:

Artificial Intelligence (AI) and Machine Learning: AI and machine learning will revolutionize manufacturing by enabling predictive maintenance, quality control, process optimization, and demand forecasting. AI-driven robots and autonomous systems will enhance efficiency and productivity on the factory floor.

Industrial Internet of Things (IIoT): The integration of sensors and IoT devices in manufacturing equipment and processes provide real-time data analytics, enabling better decision-making, reduced downtime, and improved asset management.

5G Connectivity: The rollout of 5G networks is providing faster and more reliable wireless connectivity in manufacturing facilities enabling real-time remote monitoring, augmented reality (AR), and virtual reality (VR) applications, as well as support for the increasing number of IoT devices.

Additive Manufacturing (3D Printing): 3D printing continues to expand its applications in manufacturing offering cost-effective and flexible production methods for prototypes, spare parts, and custom products.

Digital Twins: Digital twins, virtual representations of physical objects and systems, enable real-time monitoring and simulation of products, processes, and equipment, leading to better optimization and predictive maintenance.

Blockchain: Blockchain technology can enhance supply chain transparency and traceability, reducing fraud and ensuring the authenticity of products. It will become especially important in industries where tracking the origin and history of products is critical, such as pharmaceuticals and aerospace.

Human-Machine Collaboration: Augmented reality (AR) and virtual reality (VR) technologies facilitate human-machine collaboration, providing workers with real-time information, instructions, and training through immersive experiences.

The adoption and impact of these technologies are expected to drive increased efficiency, sustainability, and competitiveness in the manufacturing sector over the next decade. Manufacturers that embrace these innovations and adapt their processes accordingly are likely to be at the forefront of industry advancements. These are exiting times indeed for manufacturing and quality professionals.

In this month’s newsletter, we feature a number of these emerging technologies and their predicted impact including “Will The Metaverse Revolutionize Manufacturing Quality?”; “AI-Powered Augmented Reality for Quality Inspection”; “Data – The Foundation of Digital Manufacturing Systems”; “Increasing Role of Augmented Reality in Quality Control” and “Open Data Communication Revolutionizing Measurement Technology”. This months newsletter highlights twenty-four of the published stories – the complete library of September articles can be accessed by clicking here.

As usual I welcome your comments, news and views – my inbox is always open.

Keith Mills – Publishing Editor

Will The Metaverse Revolutionize Manufacturing Quality?

The metaverse, a term often associated with science fiction, is now rapidly becoming a reality that promises to transform various industries. Among those poised to benefit most significantly from the metaverse is manufacturing. In this article, we’ll explore how the metaverse is set to revolutionize manufacturing quality, ushering in a new era of precision, efficiency, and innovation … read more

The metaverse, a term often associated with science fiction, is now rapidly becoming a reality that promises to transform various industries. Among those poised to benefit most significantly from the metaverse is manufacturing. In this article, we’ll explore how the metaverse is set to revolutionize manufacturing quality, ushering in a new era of precision, efficiency, and innovation … read more

AI-Powered Augmented Reality for Quality Inspection

Inspection is a critical part in the quality control process in manufacturing. Quality inspection ensures that product quality and work steps performed meet the defined standards. Raw materials and components are often checked prior to the assembly process; products can also be inspected during and post-production. Frontline workers measure, examine, and test whether work steps … read more

Inspection is a critical part in the quality control process in manufacturing. Quality inspection ensures that product quality and work steps performed meet the defined standards. Raw materials and components are often checked prior to the assembly process; products can also be inspected during and post-production. Frontline workers measure, examine, and test whether work steps … read more

Factory Of The Future Smart-Manufacturing Data Platform

Renishaw’s new Central manufacturing connectivity and data platform is poised to transform the productivity, capability, and efficiency of manufacturing operations. The new data-driven manufacturing solution brings the power of connectivity to the machine shop floor, resulting in highly efficient, productive operations with optimized processes, reduced downtime and minimized waste … read more

Renishaw’s new Central manufacturing connectivity and data platform is poised to transform the productivity, capability, and efficiency of manufacturing operations. The new data-driven manufacturing solution brings the power of connectivity to the machine shop floor, resulting in highly efficient, productive operations with optimized processes, reduced downtime and minimized waste … read more

Generative AI Aids Visualizing and Analyzing 3D & CT Scans

Lumafield has unveiled Atlas, a groundbreaking AI co-pilot that helps engineers work faster by answering questions and solving complex engineering and manufacturing challenges using plain language. Atlas is a new tool in Voyager, Lumafield’s cloud-based software for analyzing 3D scan and industrial CT scan data. Along with Atlas, Lumafield also announced a major expansion … read more

Lumafield has unveiled Atlas, a groundbreaking AI co-pilot that helps engineers work faster by answering questions and solving complex engineering and manufacturing challenges using plain language. Atlas is a new tool in Voyager, Lumafield’s cloud-based software for analyzing 3D scan and industrial CT scan data. Along with Atlas, Lumafield also announced a major expansion … read more

Data – The Foundation of Digital Manufacturing Systems

The foundation of all digital manufacturing systems is data. When we think about manufacturing data, it is helpful to segregate data into two types – measured data and processed data. These two types of data originate from different sources, and each should be handled somewhat differently. Measured data originates from electronic controllers and sensors on the shop floor … read more

The foundation of all digital manufacturing systems is data. When we think about manufacturing data, it is helpful to segregate data into two types – measured data and processed data. These two types of data originate from different sources, and each should be handled somewhat differently. Measured data originates from electronic controllers and sensors on the shop floor … read more

Model-Based Enterprise – Future of the Digital Twin

Before exploring the full functionality and benefits of digital twins, it is important to understand exactly what digital twins are and how they can be applied throughout the operational lifecycle. A digital twin is, as the name suggests, a virtual model of a physical object or system that can be used to simulate the behavior of that object or system to better understand how it works in real life … read more

Before exploring the full functionality and benefits of digital twins, it is important to understand exactly what digital twins are and how they can be applied throughout the operational lifecycle. A digital twin is, as the name suggests, a virtual model of a physical object or system that can be used to simulate the behavior of that object or system to better understand how it works in real life … read more

Increasing Role of Augmented Reality in Quality Control

Quality control is a critical aspect of manufacturing where precision, consistency, and safety are paramount. Traditionally, quality control relied on human inspection and sophisticated inspection equipment. However, the advent of augmented reality (AR) has brought about a transformation in how quality control is being performed. AR technology has enabled industries to enhance their quality … read more

Quality control is a critical aspect of manufacturing where precision, consistency, and safety are paramount. Traditionally, quality control relied on human inspection and sophisticated inspection equipment. However, the advent of augmented reality (AR) has brought about a transformation in how quality control is being performed. AR technology has enabled industries to enhance their quality … read more

Measuring Stress and Strain With Highest Level of Detail

The new ZEISS ARAMIS Adjustable 24M sensor combines advanced technology with maximum flexibility. The two 24-megapixel cameras capture even the smallest details of 3D displacements and surface strain – both for point-based and full-field measurements. With its unique combination of high local resolution and image recording rate, the sensor offers precise inspection results … read more

The new ZEISS ARAMIS Adjustable 24M sensor combines advanced technology with maximum flexibility. The two 24-megapixel cameras capture even the smallest details of 3D displacements and surface strain – both for point-based and full-field measurements. With its unique combination of high local resolution and image recording rate, the sensor offers precise inspection results … read more

3D Scanning Simplifies Quality Control in Additive Manufacturing

Additive manufacturing (AM), commonly known as 3D printing, is useful for its unique ability to produce complex shapes that can outperform conventionally manufactured items. There is no tooling required as with stamping, forging, and molding, nor is material wasted as with most subtractive processes. Many individual components can be printed as a single piece … read more

Additive manufacturing (AM), commonly known as 3D printing, is useful for its unique ability to produce complex shapes that can outperform conventionally manufactured items. There is no tooling required as with stamping, forging, and molding, nor is material wasted as with most subtractive processes. Many individual components can be printed as a single piece … read more

MetrologyPackage Offers Simple Optical Sensor Integration

The AT Solution Package from AT Automation Technology has been expanded to include 3D measurement software. The new 3D solution allows for a rapid time-to-market and also opens up new avenues for 3D metrology. The new package includes a unified SDK for all AT sensors, which contains numerous new tools. 3D Measurements in Under 10 Minutes! … read more

The AT Solution Package from AT Automation Technology has been expanded to include 3D measurement software. The new 3D solution allows for a rapid time-to-market and also opens up new avenues for 3D metrology. The new package includes a unified SDK for all AT sensors, which contains numerous new tools. 3D Measurements in Under 10 Minutes! … read more

Driving Efficiency in Audi Sport’s Robotic Measurement Process

Audi Sport, a significant player in the automotive industry, faced a challenging problem. The typical cells to measure the complete BIW of cars are double cells, meaning double the cost and double the complexity. Audi Sport needed a simpler, more cost effective, and a more robust solution. The challenge was to measure both sides of the BIW with one robot, one sensor, and one turntable … read more

Audi Sport, a significant player in the automotive industry, faced a challenging problem. The typical cells to measure the complete BIW of cars are double cells, meaning double the cost and double the complexity. Audi Sport needed a simpler, more cost effective, and a more robust solution. The challenge was to measure both sides of the BIW with one robot, one sensor, and one turntable … read more

AEROStack System Automates Turbine Alignment and Build

For years, turbine engine builders have relied on manual processes for measurement and stacking to turbine alignment. These processes can be slow and rely on the skill of the operator. Automating this process is key to increasing throughput and improving engine yield while maintaining accuracy. Aero engine cores are constructed of multiple separate components … read more

For years, turbine engine builders have relied on manual processes for measurement and stacking to turbine alignment. These processes can be slow and rely on the skill of the operator. Automating this process is key to increasing throughput and improving engine yield while maintaining accuracy. Aero engine cores are constructed of multiple separate components … read more

DMG MORI Offers First End-to-End Machine Tool Digital Twin on Siemens Xcelerator Marketplace

Technology company Siemens, an innovation leader in automation and digitalization, and DMG MORI, a leading global supplier of cutting-edge machine tools for turning, milling, and grinding as well as for additive manufacturing, presented the first end-to-end digital twin for machine tool machining on Siemens Xcelerator at EMO 2023. Based on the Digital Native CNC … read more

Technology company Siemens, an innovation leader in automation and digitalization, and DMG MORI, a leading global supplier of cutting-edge machine tools for turning, milling, and grinding as well as for additive manufacturing, presented the first end-to-end digital twin for machine tool machining on Siemens Xcelerator at EMO 2023. Based on the Digital Native CNC … read more

Automatic Wafer Measurement Solution Supports Semiconductor Back-End Process Control

![]() The Industrial Metrology Business Unit of Nikon Corporation has released the automatic wafer measurement system NEXIV VMZ-NWL 200 to solve the challenges of wafer metrology in the semiconductor back-end process, where more work is traditionally carried out manually than in front-end process control. The target market is measurement centered on semiconductor manufacturing … read more

The Industrial Metrology Business Unit of Nikon Corporation has released the automatic wafer measurement system NEXIV VMZ-NWL 200 to solve the challenges of wafer metrology in the semiconductor back-end process, where more work is traditionally carried out manually than in front-end process control. The target market is measurement centered on semiconductor manufacturing … read more

Portable Hand Held Scanning Sensor Extends Photogrammetry Principle

Virtual 3D models of real objects, so called digital twins, offer numerous advantages – be it for digitization or in the quality control of industrial manufacturing. But the more complex an object, the more difficult it is to measure its shape and transfer it to a 3D model. Researchers have developed a portable hand held scanning sensor, goSCOUT3D, that enables particularly flexible 3D capture … read more

Virtual 3D models of real objects, so called digital twins, offer numerous advantages – be it for digitization or in the quality control of industrial manufacturing. But the more complex an object, the more difficult it is to measure its shape and transfer it to a 3D model. Researchers have developed a portable hand held scanning sensor, goSCOUT3D, that enables particularly flexible 3D capture … read more

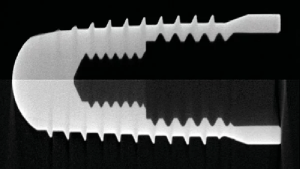

Tilted CT Improves X-ray Inspection of High Density & Flat Components

A pioneering X-ray computed laminography (CL) technique has been introduced by the Industrial Metrology Business Unit of Nikon Corporation for non-destructively inspecting challenging components using the computed tomography (CT) systems it manufactures. Called Tilted CT, the new method greatly improves voxel resolution when examining flat, high aspect ratio components … read more

A pioneering X-ray computed laminography (CL) technique has been introduced by the Industrial Metrology Business Unit of Nikon Corporation for non-destructively inspecting challenging components using the computed tomography (CT) systems it manufactures. Called Tilted CT, the new method greatly improves voxel resolution when examining flat, high aspect ratio components … read more

End-to-End Quality Inspection With CT Data Analysis

The all-digital movement is winning over manufacturers seeking more automation, connectivity and reliability from their models and machines. Surveys from the Manufacturing Leadership Council and others show strong investments and results from Manufacturing 4.0 and related digital design and manufacturing initiatives. With a robust digital framework in place comes greater agility … read more

The all-digital movement is winning over manufacturers seeking more automation, connectivity and reliability from their models and machines. Surveys from the Manufacturing Leadership Council and others show strong investments and results from Manufacturing 4.0 and related digital design and manufacturing initiatives. With a robust digital framework in place comes greater agility … read more

Optical Gear Measurement Using Digital Holography

In the recently completed ‘HoloMotion’ research project, Fraunhofer IPM has greatly enhanced the established 3D measurement method of digital multiwavelength holography in two directions: On the one hand, components in motion can now be measured with high precision for the first time. Secondly, optical gear measurement using digital holography … read more

In the recently completed ‘HoloMotion’ research project, Fraunhofer IPM has greatly enhanced the established 3D measurement method of digital multiwavelength holography in two directions: On the one hand, components in motion can now be measured with high precision for the first time. Secondly, optical gear measurement using digital holography … read more

Helical Tomography Optimizes Measurement Accuracy

With Spiral (Helical) Tomography, from Werth Messtechnik GmbH, the measured object is moved screw-like along the machine rotary axis as it rotates. This has the benefit that all parts of the measured object are irradiated horizontally from the source to the detector at least once. Due to this principle, no cone beam or ring artifacts occur, and systematic measurement errors are lower … read more

With Spiral (Helical) Tomography, from Werth Messtechnik GmbH, the measured object is moved screw-like along the machine rotary axis as it rotates. This has the benefit that all parts of the measured object are irradiated horizontally from the source to the detector at least once. Due to this principle, no cone beam or ring artifacts occur, and systematic measurement errors are lower … read more

Digital Platform Provides Machine Tool Monitoring System

Automation has emerged as a game-changer for manufacturing, enabling companies to enhance productivity, reduce costs, and improve safety. Machine tools, automated assembly lines, and smart material handling systems are just a few examples of automation solutions that can significantly increase production rates while minimizing errors. Monitoring and measuring systems … read more

Automation has emerged as a game-changer for manufacturing, enabling companies to enhance productivity, reduce costs, and improve safety. Machine tools, automated assembly lines, and smart material handling systems are just a few examples of automation solutions that can significantly increase production rates while minimizing errors. Monitoring and measuring systems … read more

Open Data Communication Revolutionizing Measurement Technology

Measurement technology is playing a major role in Industry 4.0. A crucial factor for the success of the digital transformation is the OPC UA GMS (geometric measuring systems) interface, which a working group of the VDMA hopes will pave the way for vendor-neutral communication in measuring.Quality is decided by the precision of the instrument, Henry Ford once claimed. The automotive pioneer who originated quality management would surely be amazed at the precision offered … read more

Measurement technology is playing a major role in Industry 4.0. A crucial factor for the success of the digital transformation is the OPC UA GMS (geometric measuring systems) interface, which a working group of the VDMA hopes will pave the way for vendor-neutral communication in measuring.Quality is decided by the precision of the instrument, Henry Ford once claimed. The automotive pioneer who originated quality management would surely be amazed at the precision offered … read more

Automated Stamped Parts Loading Through 3D Container Inspection

Robots perform monotonous workflows and less pleasant, repetitive tasks with brilliance. Combined with image processing, they become ‘seeing’ and reliable supporters of humans. They are used in quality assurance to check components, help with the assembly and positioning of components, detect errors and deviations in production processes and thus increase efficiency … read more

Robots perform monotonous workflows and less pleasant, repetitive tasks with brilliance. Combined with image processing, they become ‘seeing’ and reliable supporters of humans. They are used in quality assurance to check components, help with the assembly and positioning of components, detect errors and deviations in production processes and thus increase efficiency … read more

Cognex To Acquire Global Leader In Machine Vision Optics & Advanced Imaging Solutions

Cognex Corporation, a leader in industrial machine vision, has announced it has agreed to acquire Moritex Corporation from Trustar Capital, a private equity affiliate of CITIC Capital Holdings Limited, for ¥40 billion (approximately $275 million), in an all-cash transaction. Moritex is a leading global provider of optics components with a strong presence in Japan … read more

Cognex Corporation, a leader in industrial machine vision, has announced it has agreed to acquire Moritex Corporation from Trustar Capital, a private equity affiliate of CITIC Capital Holdings Limited, for ¥40 billion (approximately $275 million), in an all-cash transaction. Moritex is a leading global provider of optics components with a strong presence in Japan … read more

MES Platforms Provide Digital Transformation To Create Smart Manufacturing Plants

The Fourth Industrial Revolution is based, above all, on automation and real-time analytics. It combines robotics, artificial intelligence, 5G connectivity, industrial IoT, digital twins, augmented reality, cloud computing and big data, among other innovations. They all work towards the same goal: operational efficiency. MES (manufacturing execution system) is one of the 4.0 technologies … read more

The Fourth Industrial Revolution is based, above all, on automation and real-time analytics. It combines robotics, artificial intelligence, 5G connectivity, industrial IoT, digital twins, augmented reality, cloud computing and big data, among other innovations. They all work towards the same goal: operational efficiency. MES (manufacturing execution system) is one of the 4.0 technologies … read more

Receive the #1 online digital metrology magazine directly into your inbox featuring the very latest news from the manufacturing metrology and smart manufacturing sectors

Unsubscribe at any time. Metrology News will protect your personal information as stated in our privacy policy. Your email will not be shared, bartered, or sold to any third party organization. HOME PAGE LINK

HOME PAGE LINK