Adapting with agility with the latest vision and artificial intelligence capabilities

November 10, 2023

By

Sukanya Ray Ghosh

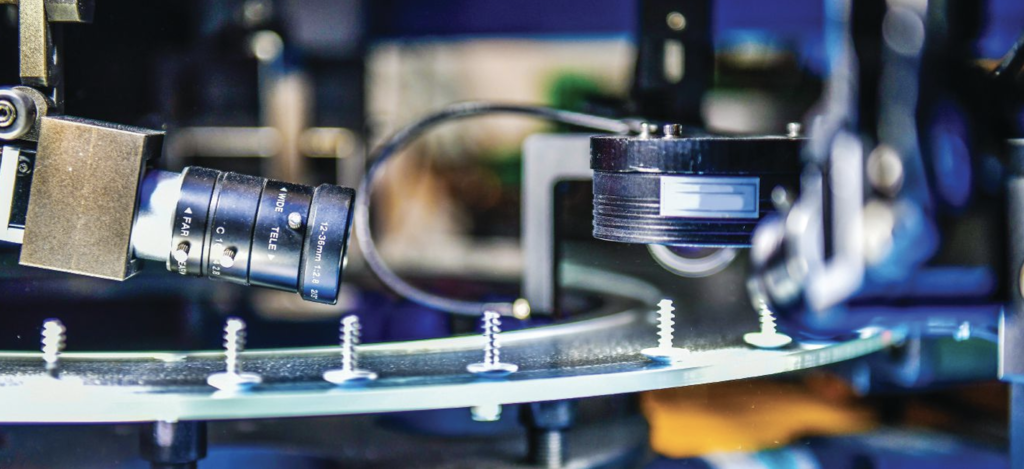

With Industry 4.0 technologies, such as vision systems, manufacturers can ensure quality consistency even when adding new or altered products to existing production lines. PHOTO: MJ_Prototype / iStock / Getty Images

With Industry 4.0 technologies, such as vision systems, manufacturers can ensure quality consistency even when adding new or altered products to existing production lines. PHOTO: MJ_Prototype / iStock / Getty Images Implementing agile manufacturing production processes with Industry 4.0 technologies can be a transformative endeavour for small and medium-sized manufacturers (SMEs). Agile manufacturing places a strong emphasis on responding rapidly to ever-changing customer demands. In a market that is highly competitive, reacting quickly and intelligently to market conditions can prove to be a game changer for SMEs.

Jonathan Weiss, CRO of Eigen Innovations, says that meeting the ever-changing landscape of demand is one of the most important challenges for all manufacturers, whether big or small. “I see the most value for manufacturers coming from the tools that can help augment and complement people in the workplace. It’s not uncommon to hear about how technology is going to take jobs away from people in manufacturing facilities, but I don’t really see it that way. I see technologies augmenting skills that have either left the workforce and have not re-entered, or as tools to help folks upskill into new types of roles,” he says.

Yassir Rizwan, co-founder and CEO of Labforge, explains that SMEs often tend to rely on older processes. Although they are aware of technologies like machine vision and artificial intelligence (AI), these are not on their priority list. “They have existential fires happening and need to put out these fires first. For example, labour is expensive. Raw materials are expensive. They have competition from abroad. Shipping products is expensive. So, unless vision systems or AI are going to affect their core processes or the core priority items, they are low on their task list,” he says.

Rizwan adds that when SMEs can take the time to do a deep dive and add some kind of automation at their facilities, they are able to gain quality improvement and consistency of their products, along with labour savings and increased throughput.

For example, says Rizwan, if a small bread manufacturer producing 200 loaves of bread per day were to consider adding a vision camera system to check the bread colour, it could ensure the consistent taste of its products.

Barriers to adoption

Implementing machine vision and AI technologies can be expensive. SMEs often struggle to allocate the necessary funds for hardware, software and skilled personnel to projects that are not critical for their survival. It is crucial, in such circumstances, to start by identifying specific pain points or areas where agility is crucial in their production processes. There is a need to define clear objectives for implementing AI and machine vision technologies, such as improving quality, reducing downtime or increasing production speed.

Rizwan shares that while vision and AI can indeed help SMEs respond quickly to market and customer demands, these technologies have a high barrier to entry. “The biggest problem is there’s a learning curve. There’s a lot of jargon, usually industry terminology that people don’t understand and terminology that people often get defensive about. And understandably so, because the industry is moving very fast. Keeping up with AI technology is a limitation for small manufacturers. It turns out that AI and machine vision experts also cannot keep up with all the advancements in this field, they can only focus on their own sub-fields,” he explains.

He adds that without the presence of in-house expertise, technology can turn into a bane rather than a blessing. For example, he says, a manufacturer adds machine vision and cameras with the help of an external expert to perform a specific task like identifying product consistency. However, two months down the road, the customer demand changes and there is a need to alter the product slightly. The manufacturer has to ensure that the camera is now checking for consistency of the altered product.

“So, the question for the manufacturer is do they modify the requirements on their own or do they spend the extra and get an expert? I think the answer to this going forward is going to be tools that are easy enough for manufacturers to use themselves and modify themselves. The key is to give them the tools to make those small changes themselves rather than having to go back to the experts and re-integrate everything and redo everything. Most tools currently in the market are not like that. They’re tools targeted towards experts,” explains Rizwan.

Changing the game with AI

Automated quality control of products is one of the many ways in which SMEs can ensure a quicker response to changing market conditions using vision and AI technologies. These technologies can help them forecast demand and optimize their supply chains. For companies that do not have surplus funds, these small changes can go a long way in ensuring long-term survival.

Hugues Foltz, executive vice-president of Vooban, says that for SMEs, AI, for instance, can not just optimize the production processes, it can even optimize the scheduling of all production.

“For example, even if it’s a new product, there’re always sub-assemblies that can be reordered and rescheduled in a better way than just taking a new product that is in demand and putting it in line as ‘first-in-first-out’, which is not productive at all. Those processes can be optimized using operational research by looking at the best formula and the best recipe to achieve the same task,” he says.

Foltz explains that this is similar to using Google Maps to figure out the best route to reach a destination while factoring in distance, traffic, road closures and so on.

With limited resources on hand, SMEs need to be armed with all the right tools to stay ahead of the game. AI can be a major game changer here, shares Foltz.

How can this technology help SMEs react rapidly to customer demands? Foltz says that AI can help predict sales, prepare for the changes and allocate manpower to the production processes accordingly. AI can also help manage stock and inventory as per the most current requirements.

Manufacturers can leverage AI to predict process, sales and other outcomes in advance, reducing the need for last minute adjustments to fulfill customer demands. PHOTO: Ekkasit919 / iStock / Getty Images

“The right prediction depends on the market and the industry. In general, with the right data available from government reports, industry representatives and industry associations, small and medium-sized manufacturers can predict when there will be a rise in demand in each market, even a year in advance in some cases. Using AI, they can react to the market conditions. Those predictions can come in 80 percent accurate almost a year in advance,” says Foltz.

He adds that while AI is a very powerful tool, SMEs will need additional information such as two years of sales history of the company, industry trends, market variables and so on. “We can train an algorithm to predict the future easily based on this,” he says.

Adaptable technology

Many manufacturers today work in a high-volume or low-volume production environment with high variability, where the same products are not produced week after week.

Weiss explains that it can be challenging to understand the changing products and make them to the highest quality standards possible.

Eigen Innovations, which specializes in machine vision systems and software, can help SMEs compare the products they make to their CAD model rendering, for example, thus helping them make real-time decisions regarding the quality of the parts.

In addition, Weiss emphasizes the importance of interoperability of all tooling so that technology additions and changes to the production lines are quicker. Interoperability also enables manufacturers to automate actions and processes based on quality indicators.

“You might need to make a significant change in production, whether you’re reconfiguring lines or you’re introducing new SKUs, new product configurations and so on. There are a lot of changes that need to be made. MES systems change. SCADA systems get new parameters. SPC or statistical process control and tooling changes happen. With your vision systems, you are looking at the new products. So, what does that mean? You need new machine learning models so the cameras know what they’re seeing. Interoperability of the tooling is needed so that your camera system, for example, is not on an isolated island where it requires a tremendous amount of dedicated support to adapt to the other processes that are evolving,” explains Weiss.

He adds that when adding Eigen’s vision systems at manufacturing facilities, the team has integrated the technology with MES systems, PLCs and control networks, among other things.

“Fundamentally, you only get a certain level of value when you’re informed about a defect. You get exponentially more value out of the system when you can actually do some closed-loop automation, such as taking the bad products off the line or doing something autonomous to prevent a customer from getting a bad product,” explains Weiss.

He says that with the kind of agility needed in today’s manufacturing environment, interoperability is required to be able to adapt.

A real-life implementation

Examples of how SMEs have been able to adapt to the market with AI, vision and other Industry 4.0 technologies abound.

Foltz shares how Stove Builder International (SBI), a manufacturer of stoves and furnaces in Canada, implemented AI to its advantage. SBI, according to Vooban, had invested significantly in automation already before they approached Vooban. They wanted to implement AI.

“The first project they had in mind was sales prediction. Sales prediction is a very good quick win in many cases. SBI had a seasonality challenge. During peak seasons, it often had to manage the impact of labour shortage on its business. SBI needed to produce more products for a few months to fill inventory to appropriate levels,” explains Foltz.

He adds that this issue added to the cost for the company. With a good sales prediction algorithm, Foltz’s team managed to bring them enough information and enough confidence in what they were going to sell the next year. This prediction would allow them to carry on production at the same pace all year long. The payback, says Foltz, was instantaneous.

“Implementing AI ensured that they are not in firefighting mode during the peak season when customer demand is high. This makes life easier for everyone,” notes Foltz.

For SMEs, every win counts, and every success matters. Industry 4.0 technologies available today can be crucial in helping them tackle changing demands quickly without compromising on the quality of their products.

Advertisement

- OTTO Motors launches heavy-duty AMR for compact spaces

- OPC UA publishes metaverse concept, real world examples for digital twins in automation