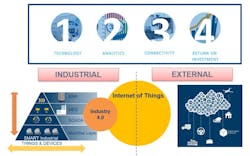

The Fourth Industrial Revolution is here, and it's bringing new ways to generate revenue and tackle manufacturing challenges. Industry 4.0 marries traditional manufacturing with technology, using smart equipment and automation to analyze, monitor, self-diagnose and communicate with other machines and co-workers.

However, five key challenges tend to slow manufacturers’ transition to Industry 4.0: IT systems, legacy equipment, workforce, new processes and funding. To overcome these challenges, be sure to maintain focus on the four key elements that comprise a digital strategy: the business case, connectivity, analytics, and technology selection and adoption.

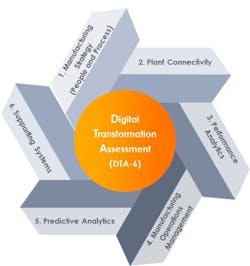

If you’re ready to take on the challenges of Industry 4.0, be aware that the keys to a smooth transition lie in assessing digital maturity and implementing a long-term digital transformation strategy that aligns with people, processes and technology.

Here are five tips toward a successful digital transformation.

1. ROI first — start with the business case:

- Measure success through improvements in uptime, asset utilization, reduction in scrap and overall labor productivity.

- Tie technology selection and adoption to the business case.

- Emphasize financial impact and return on investment (ROI) for a sustainable transformation.

2. Get connected — real time data is the foundation:

- Collect real-time data from the plant floor.

- Choose key data streams aligned with the business case.

- Consider machine capability, cost, time, data types and sources when connecting the plant floor.

3. Track metrics — gain true visibility to improve performance:

- Utilize real-time data for actionable metrics and overall visibility.

- Measure key metrics like OEE (overall equipment effectiveness), TEEP (total effective equipment performance), MTBF (mean time before failure) and MTTR (mean time to repair).

- Provide the right information to the right role at the right time and drive improvements based on real-time data insights.

4. Execute shop to top — integrate production, inventory, quality and maintenance:

- Follow the ISA-95 reference model for manufacturing operations management.

- Extend connectivity from the shop floor to business systems like ERP.

- Implement modular functionality for production, inventory, quality and maintenance activities.

5. Predict and prescribe — drive toward zero-downtime, zero-defect manufacturing:

- Implement predictive analytics using artificial intelligence tools (such as machine learning) for predictive maintenance and predictive quality insights.

- Use connected data for real-time OEE analytics and predictive insights.

- Move towards prescriptive analytics for automated decision-making in real time.

It’s important to emphasize that a successful digital transformation not only involves smart-connected factories and assets, but also connected workers. It advocates for intuitive human-machine interfaces, wearables and augmented reality to enhance worker productivity, quality, training and remote assistance.

Though this column provides an outline of the key steps toward making a successful digital transformation, we realize it’s a lot to take in. As you refer back to this list, always keep in mind these key take-aways to keep you on track:

- Align people, processes and technology for digital transformation.

- Initiate the transformation with an Industry 4.0 training and assessment, leading to a proof of value pilot.

- Track success, replicate best practices and establish an internal center of excellence.

- Maintain a zero-downtime/zero-defect vision, leveraging technologies in an ROI-based manner.

Dr. Mo Abuali is senior director at Wipfli, a partner member of the Control System Integrators Association (CSIA). For more information about Wipfli, visit its profile on the CSIA Industrial Automation Exchange.