Quantum computing and industrial automation: A revolution in the making

December 4, 2023

By Stephanie Holko, NGen

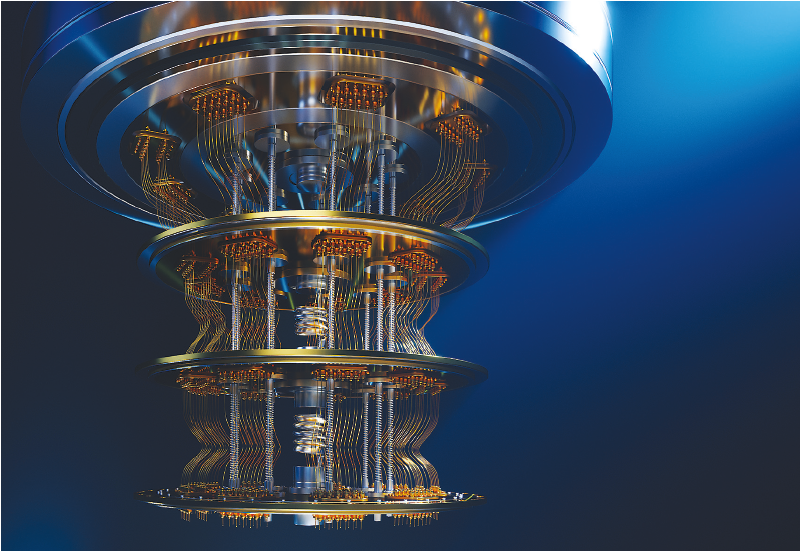

PHOTO: Bartlomiej Wroblewski / iStock / Getty Images Plus

PHOTO: Bartlomiej Wroblewski / iStock / Getty Images Plus Since the 1950s, computing has revolutionized manufacturing. Early computing, like Computer Numerical Control (CNC), aimed to enhance machining quality and productivity. These computers were large, cost a lot of money and were used for a specific, limited purpose. They needed specialized expertise and new components. Quantum computing today resembles this nascent stage, but its potential for the next 70 years is immense.

Beginning with CNC machining in the 1950s and 60s, industrial automation took its first strides with computing. What followed was computer-aided design (CAD) and computer-aided manufacturing (CAM). These new tools made digital versions of products, parts and machines, allowed for better communications between design teams and production, and improved accuracy and reproducibility. Industry 3.0 emerged with process control systems, robotics and enterprise resource planning (ERP) systems in the 1970s through the 1990s. As computing technology evolved, more economically viable tools emerged, leading to the integration of simulation, modelling, automation, internet connectivity and artificial intelligence into manufacturing processes.

While quantum materials and sensors have been around for a while, quantum computing as a part of manufacturing is in its infancy. It is a fundamentally different method of processing data from classical computing. Instead of the binary ones and zeros we are familiar with, it can process many calculations simultaneously. This potential promises to address previously insurmountable challenges in modeling, simulation, materials discovery, and optimization within the next decade.

The approach to complex problem-solving will change with the adoption of quantum computing, analogous to the computation difference from 70 years ago to today. For example, materials discovery has shifted to simulation built on existing data and extrapolation of preferrable properties in new materials.

Quantum computing is eventually expected to take compute-heavy calculations down to seconds or less. The ability of a quantum computer to solve problems that no classical computer can solve in a reasonable amount of time is known as “quantum advantage.” While there are very few examples of quantum advantage that have been demonstrated to date, more are sure to come.

There are good reasons to consider quantum computing as part of your long-range strategy, including risk mitigation. Most prevalent are the cybersecurity risks that could impact encryption on existing data systems. While some operation technology systems are separated from information systems by the so-called demilitarized zone in the classic Purdue architecture, the Internet of things and other architectures could be impacted by encryption-breaking technologies enabled by quantum computing.

On the flip side, there are many applications that are expected to solve more complex problems that are treated as the cost of doing business today because it is too complex to address. For example, quantum computing could positively impact industrial performance by helping to solve heady problems like optimizing logistics in a larger-scale network or supply chain.

Challenges to deploying quantum computing in an industrial setting include the reliability of the results from current quantum computers and the scalability of quantum computing to the level required by industry. Every day there are developments to mitigate errors in program outcomes and to develop quantum computers with more capacity and accessibility.

There are also societal impacts to consider, as with any breakthrough technology. Access to technology by smaller companies and access to training for employees and underserved communities will be important to consider as quantum gains traction. There are ethical considerations in ensuring data bias does not amplify inequities, similar to the concerns with artificial intelligence. Developing quantum technologies while considering the environmental impact – not just of data processing, but of manufacturing and running quantum computers – will be important as well.

Canada is a leader in quantum technologies and has published a National Quantum Strategy to strengthen this advantage. Canadian manufacturers are uniquely positioned to engage with Canadian quantum technologies and to become specialty suppliers to the quantum hardware industry. There is a recently announced funding to support the commercialization of technologies in quantum computing as well as quantum sensing and quantum communications.

Stephanie Holko is the director of project development at Next Generation Manufacturing Canada (NGen). She loves connecting emerging technologies with existing manufacturing problems and believes the future of manufacturing is in the adoption of new ways of working. Stephanie is a licensed Professional Engineer in Ontario.

Advertisement

- Balluff Canada marks milestone anniversary with open house event

- Report: Downturn in Canadian manufacturing continues in November