A group of international scientists are working on an “inkable” nanomaterial that could become a spray-on electronic component for ultra-thin, lightweight, and bendable displays and devices.

The group, led by RMIT University’s Associate Professor Enrico Della Gaspera and Joel van Embden, are looking into the potential of zinc oxide to be incorporated into many components of future technologies.

Della Gaspera said recent progress in nanotechnology has enabled the team to greatly improve and adapt the properties and performances of zinc oxide by making it extremely small and with well-defined features.

“Tiny and versatile particles of zinc oxide can now be prepared with exceptional control of their size, shape and chemical composition at the nanoscale,” van Embden said. This enables precise control of the resulting properties for countless applications in optics, electronics, energy, sensing technologies, and even microbial decontamination, he explained.

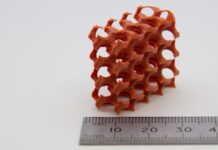

In a media release, the team described how the zinc oxide can be formulated into ink and deposited as an ultra-thin coating through a process similar to ink-jet printing or airbrush painting.

“These coatings can be made highly transparent to visible light, yet also highly electrically conductive – two fundamental characteristics needed for making touchscreen displays,” Della Gaspera said.

The inkable nanomaterial can also be deposited at low temperatures, allowing coatings on flexible substrates, such as plastic, that are resilient to flexing and bending.

According to the study’s proponents, zinc oxide nanocrystals has a wide array of potential applications, such as self-cleaning coatings, antibacterial and antifungal agents, sensors to detect ultraviolet radiation, electronic components in solar cells and LED, transistors, and sensors that could be used to detect harmful gases for residential, industrial, and environmental applications.

The team said it still needs to address the shortfall in electric conductivity that nanocrystal coatings have when compared to industrial benchmarks.

“The intrinsic structure of the nanocrystal coatings, which enables more flexibility, limits the ability of the coating to conduct electricity efficiently,” they noted in the press statement.

“We and other scientists around the world are working towards addressing these challenges and good progress is being made,” Della Gaspera said.

He sees great opportunities to collaborate with other organisations and industry partners to tackle these kinds of challenges.

Professor Silvia Gross from the University of Padova in Italy and Associate Professor Kevin Kittilstved from the University of Massachusetts Amherst in the United States are co-authors in the study.