3 Capabilities of an Electronic Manufacturing Services Company

The process of manufacturing in-demand gadgets like phones and TVs follows several phases. In effect, the original equipment manufacturer (OEM) has to research and develop a design that meets current consumer needs.

Because of these current demands, most manufacturers build their products in-house or outsource related tasks. The latter has become a standard option for most OEMs as they focus on researching possible product improvements.

The subcontractors who handle these tasks do so in what’s referred to as electronic manufacturing services (EMS). Specialized engineering experts like Nortech Systems help OEMs attain their project goals.

The cost will depend on the complexity of the tasks and the current stage of product development.

So, what’s EMS, and what capabilities does a provider of these services have? Keep reading to learn more about this intriguing concept.

What is EMS?

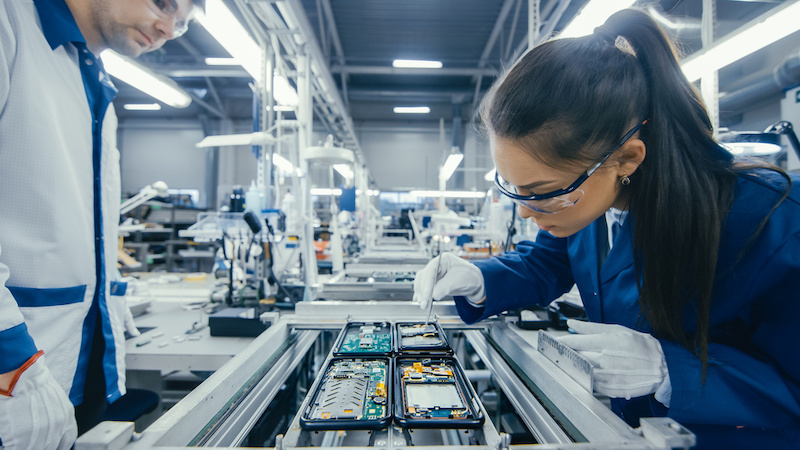

Also known as electronic contract manufacturing (ECM), EMS refers to companies specializing in testing, manufacturing, and distributing electronic components on behalf of OEMs.

They also provide repair or return services to renowned manufacturing companies. With the growing demand for outsourcing these tasks, EMS providers have become very popular in recent years.

But why is there a growing demand in this sector? The best explanation for this phenomenon is that most companies have dedicated their time to research and development.

A typical OEM usually focuses on the trends in consumer demands, researches the best solution, and consequently designs it.

Rather than spending more time developing new products, they can outsource the rest of the process to EMS providers. This way, they can focus on customer feedback and design new or find relevant improvements to their current products.

Capabilities of an EMS company

OEMs can enjoy many benefits from outsourcing their tasks to contract manufacturers. Regardless of your specialty in the electronics industry, an EMS can improve your product development process. That said, here are three essential capabilities of an EMS provider:

1. Offer electronic engineering services

Among the services that EMS companies offer are electronic engineering services. This service involves turning an OEM concept into a functional and validated product. For instance, suppose you have an idea of building a gadget to enhance communication.

That means you have to present your concept, and the EMS provider will create the device based on your research and design.

Usually, electronic engineering companies design printed circuit boards (PCBs), integrate all the necessary components, and develop custom housing. Suppose you’re unsure what to use for your casing. The EMS provider will advise you on the best material depending on your circuit and its purpose.

Some of the services that fall under this category include the following:

- Breadboarding and simulation

- 3D modeling and enclosure design

- Contract PCB layout

- Validation in compliance with various regulations like environmental and user safety

2. Offer PCB assembly services

A PCB is a board on which manufacturers socket or surface-mount components in most electronic gadgets. The process of achieving this board can be quite complex. It starts with designing the concept product and then printing that digital circuit on a physical board, which you see in most electronics.

Surface-mount technology has become the most preferred method in PCB development because it involves less human interaction. Its improved accuracy and enhanced product lifespans are other reasons OEMs have opted for this innovative technique.

Most EMS companies have the necessary machines and resources to accomplish this task. In addition, contract manufacturing engineers are skilled in printing and testing the usability of PCBs.

3. Full functional in-house testing

Another vital service that EMS providers offer is testing the final designs. As an OEM, you’d want to market a new electronic gadget that’s fully functional. Anything less than that, and you can potentially mess up your project or supply chain.

OEMs employ contract manufacturers to carry out all the necessary tests at the end of the development process to avoid spending money repairing avoidable faults. The engineers will do a visual inspection, test the continuity of the circuits, and check if the PCB is operating as intended.

Burn-in testing, flying probe testing, and in-circuit testing are among the main tests manufacturers carry out on any PCB.

Growing demand

A typical electronic manufacturing service provider has a lot to offer. Electronic engineering, PCB assembly, and in-house testing are some of the basic tasks you can employ an EMS provider to do for you.

However, you can get many other services from them, including prototyping, electromechanical assembly, and aftermarket services. With growing consumer demand, especially in the tech world, contract manufacturers will become even more popular.