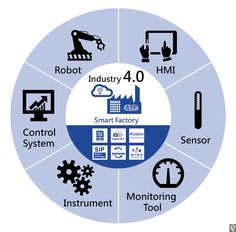

This model is designed to measure the Industry 4.0 maturity of manufacturing companies. It is based on a combination of Industry 4.0 research and practical experience.

Industry 4.0 is the subset of the fourth industrial revolution that relates to Industry. Broadly speaking it is the use of cyber-physical systems, strategies and processes to improve industrial productivity, capability and performance.

If you are thinking that Industry 4.0 is about technology improving manufacturing, then you are missing an extremely key point.

Industry 4.0 is not a panacea and is not about technology, it’s about a philosophy and strategy for how you approach your industrial processes. Technology can play a part in helping deliver success, but Industry 4.0 is about far more than that. At its heart it is about using data to make the right decisions.

It is also not just about cost savings and efficiencies, it covers all aspects of industrial processes from production to supply chain, in many sectors from manufacturing to energy, from transportation to food. As with the previous industrial revolutions (mechanization, mass production, automation) over time it becomes a story of survival, those companies that adopt new approaches and ways of doing things survive others do not.

The purpose of this model is to help assess the maturity of a company in their journey to Industry 4.0.

Each company’s journey will be different, there is no right or wrong answer, and there is no defined end point. This model is designed to cover many aspects from the basic (simple data collection) to the very advanced (lights-out factories run through AI).

Each company will decide which pieces are appropriate to them given their individual circumstances, skills and funds available. Do not expect every company to be “Advanced” in every category, very few will be, and even those that are good are likely to only be advanced in certain areas.

The Maturity Model Criteria

This model is built around a series of criteria grouped into six categories:

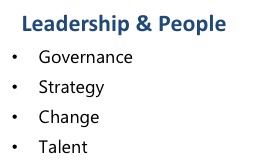

- Leadership & People

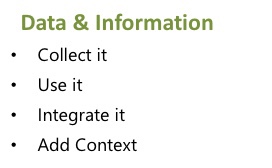

- Data & Information

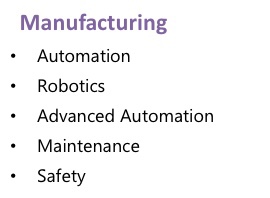

- Manufacturing

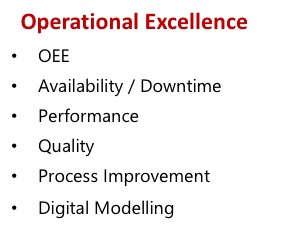

- Operational Excellence

- Supply Chain

- Technology

Each area is explained further below.

To be successful with any major change, Leadership & People must be considered. Key to this is putting in place appropriate Governance to control the program and ensuring that you have developed a Strategy to map your path to future success.

It is also critical to develop your approach to Change Management to ensure that new ways of working are developed and embraced by the workforce.

Last but not least is finding the right Talent with the right skill sets. This does not mean you have to hire them, it could be finding the right partners to help.

The second category is Data & Information, which is the heart of Industry 4.0. How you collect, store and use the data is fundamental to your future success. Do you know how your machines are performing, or how often they are idle? Data is the lifeblood of Industry 4.0.

Advanced Manufacturing, including automation and robotics is what most people think of when they talk Industry 4.0, but these will only get you so far. Without a proper data driven approach these machines can end up sitting idle and costing you money.

Maintenance is another critical part of Manufacturing, one where data can be used to drive massive differences in downtime, repairs and costs. Approaches ranging from Condition Based through to Predictive and Prescriptive Maintenance all rely on good data to drive them.

Lastly, do not forget safety, there are technology and data driven approaches that can improve both your safety and your productivity.

The fourth category is Operational Excellence, a set of techniques that are well known to many and include OEE and its component parts at its heart. It also embraces techniques such as Lean and 6-Sigma to drive improved results.

An area often neglected is Supply Chain. Having full awareness of your upstream and downstream supply chain will help you to better plan your production and avoid disappointing your customers. Obviously, there are far more advanced opportunities as practiced with large Automotive production facilities, but starting with the basics will provide considerable benefits.

Last, but not least, Technology. Another area people often associate with Industry 4.0, including use of low cost wireless IoT sensors to provide more information, and internet connectivity to allow everything to be connected.

Other new technologies such as Augmented and Virtual Reality can provide real advantages and benefits to a company. For example, the ability for a remote technician to guide one of your maintenance staff through a complex repair from thousands of miles away.

Summary

We hope you have found this whistle stop tour of our Industry 4.0 Maturity Model useful. If you would like to know more then please contact us via the link at the bottom of the page and we will be happy to discuss how it can be used and applied.

A more detailed overview of the Industry 4.0 Maturity Model can be found here.

One thought on “Industry 4.0 Maturity Model”