Automated CAM Programming – Is Your Software Really Delivering?

Sponsored ContentA look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Share

Manufacturers are experiencing a perfect storm, with stretched supply chains, increasing cost of goods and materials, and the ever-present skills gap. At times it can be challenging to survive – let alone grow. You might initially think that the quality of your machined parts is the key differentiator here, and yet the reality is success lies in your ability to reduce waste and cost. Do this and you’ll deliver projects quicker and get them right the first time, every time.

Top shops reflect on their performance

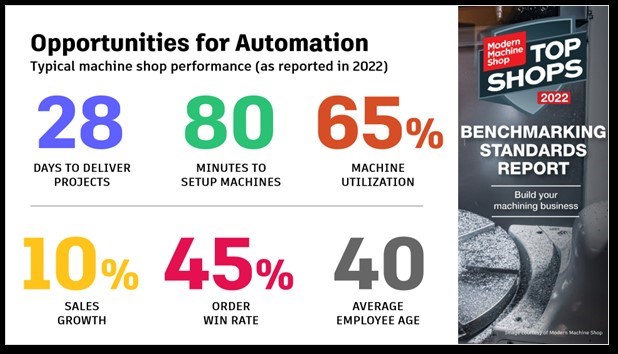

In the 2022 Modern Machine Shop Top Shops Survey, hundreds of manufacturers shared insights into the previous 12 months:

Modern Machine Shop’s 2022 “Top Shops” survey revealed interesting insights.

- Typical project delivery time = 28 days

- Average machine setup time = 80 minutes

- Average machine utilization = 65%

- Sales Growth = 10%

- Order win rate = 45%

- Average age of employee = 40

Automation opportunities through CAM software

Automation. It’s not a new idea – in fact, we’ve been automating manufacturing processes for decades. Even with the latest advances in machine tool automation, shop-floor palletization and manufacturing software, there are still plenty of opportunities to remove manual processes, save time, reduce waste, improve consistency and shorten delivery times.

It won’t surprise you to hear that modern CAD/CAM software can help with automation, including.

- CAM templates

- Intelligent “whole part” strategies

- Automated part setup

- Integrated CAD/CAM workflows

- Cloud-enabled collaboration

CAM templates – turn your secret sauce into repeatable manufacturing success

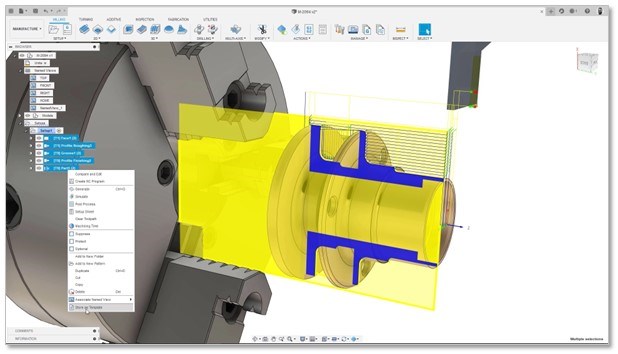

CAM templates allow you to capture your manufacturing best practices—including preferred machining strategies, tool assemblies, stock materials and cutting parameters—and apply them to your 3D CAD models, automatically generating all the NC code you need.

CAM software can store complete machining processes as templates that can be automatically applied to parts. All Images Source: Autodesk

UK-based Brown & Holmes (Tamworth) Ltd recently invested in shop-floor CAM software to automate part programming. Their experienced programmers created templates that were shared with less experienced workers on the shopfloor. This removed the reliance on the programming office and allowed the shop-floor team to be independent and productive. The experienced workers were also freed up to focus on more challenging projects, which saw order books double and non-conformance reduce by a staggering 34%.

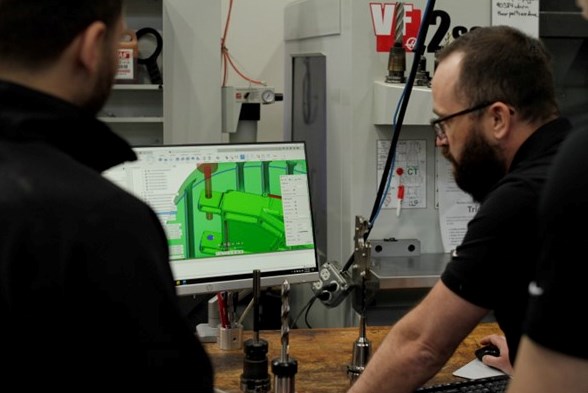

UK-based Brown & Holmes (Tamworth) Ltd use automated CAM programming on the shop-floor to remove major production bottlenecks.

Intelligent “whole part” strategies – simplifying complex part programming

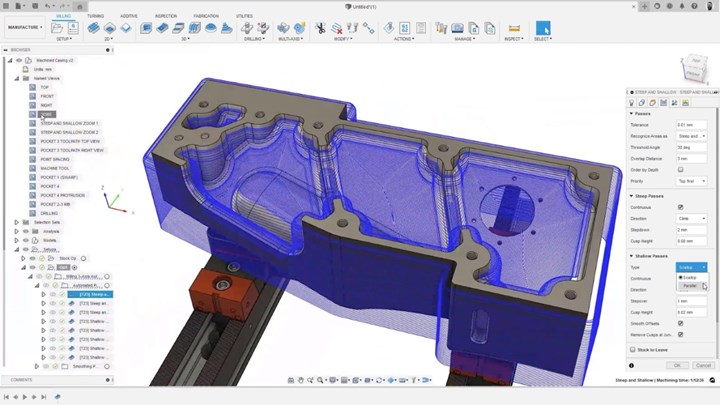

Programming today’s increasingly complex parts takes time and skill. In recent years, CAM software has addressed this by offering whole part machining strategies that can automate the programming of these shapes. Strategies like “Steep and Shallow Finishing” can analyze the surface geometry and automatically apply the optimum strategy to machine the zones in the most effective way.

Whole part strategies simplify part programming by intelligently machining different regions to achieve a consistent surface finish.

Advanced controls over toolpath angles, wall clearance, spiral motion, cusp removal, and smooth offsets produce buttery-smooth machine motion, reducing the need for manual rework and reducing project delivery.

Automated part setup – unlock free money from your CNC machines

Returning to the MMS Top Shop survey of 2022, respondents stated an average 80 minutes for machine setup. Setting up the part represents a considerable portion of this overall time and is often a manual process requiring considerable skill and time.

Replacing manual part setup with an automated process can easily reduce machine setup time by 82%.

Automation can help here too. Replacing this manual process with one using spindle mounted probes can save hours and avoid human error. CAM software can create NC programs that use the probe to measure the un-machined stock, then load the measurements back into the software to adjust the machining operations to fit. In a recent example, a complex part was set up manually using gauges, which took 15 minutes and 10 seconds. The testers then set it up again using automated probing and alignment in CAM software, taking only 2 minutes, 40 seconds). That’s a time saving of 82%.

Pittsburgh-based Conturo Prototyping use automated part setup in Fusion 360 to avoid costly machine downtime.

Pittsburgh-based Conturo Prototyping LLC has been using spindle-mounted probes for years and has seen considerable benefits. As Patrick Fee, supervisor, explains, “In a recent job we were on the verge of having to scrap and reorder well over $200 in material and have our machine sitting idle the rest of the day. Probing and part alignment allowed us to automatically adjust the machining so that the part fit in the stock.”

Integrated CAD/CAM workflows

Some manufacturers have historically used separate software products for design (CAD) and manufacturing (CAM) activities. This disjointed approach increases the risk of mistakes and delays, especially when design revisions are made.

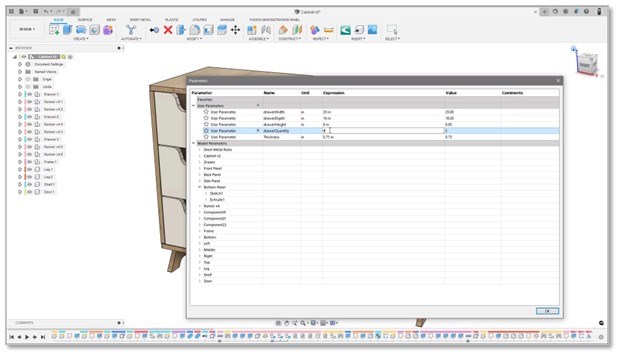

By comparison, an integrated CAD/CAM solution stores all data in a single location – meaning 3D models, drawings, and manufacturing information are all connected and accessible by any team member. If the design team makes a change, the data updates instantly, informing the manufacturing team so they can quickly decide how to react. This integrated solution also provides automatic associativity, meaning work-holding, fixtures, nested parts, setups and toolpaths can all update seamlessly, reducing the risks associated with change orders and helping manufacturing teams be more productive.

Integrated CAD/CAM simplifies changes and ensures design & production teams are always in-sync.

Cloud-enabled collaboration

There’s no denying the positive impact that the cloud is having on life – and that’s certainly true in the manufacturing business. If recent events have taught us anything, it’s the importance of helping teams to collaborate more effectively to allow critical decisions to be made quickly. And yet, it’s surprising just how many shops still rely on files and emails for communication.

While these certainly offer benefits over paper-based collaboration systems, they’re not agile or flexible enough to allow teams to succeed and often cause delays and production errors. The cloud changes this as data is stored centrally and securely, ensuring everyone is working on the latest data, with access anywhere, anytime and on any connected device.

Cloud-enabled software allows teams to collaborate seamlessly, allowing critical decisions to be made faster.

Combining integrated CAD/CAM with cloud-enabled collaboration allows machine programmers to share NC code and setup sheets with machine operators. At the same time, operators can share tool libraries with programmers and designers can instantly communicate design changes to the entire team. Cloud-based collaboration helps teams connect, whether they’re across the hall or across the world.

Summary

Manufacturers are under pressure to meet their customer expectations in terms of speed, agility, efficiency, and price. While supply chain and inflation-related cost concerns certainly do exist, the effective use of modern, connected, manufacturing software, such as Autodesk Fusion 360, is one of the easiest ways to overcome them. By automating common part programming tasks, teams can save time and avoid waste, whilst also increasing machine utilization and shortening overall project delivery times.

Learn More

For more information on automated CAM programming with Autodesk Fusion 360 visit Autodesk.com.