Smart manufacturing has surged in relevance. But making the concept a reality requires cultural consensus.

Brian Buntz recently discussed this with me and his take was recently published in IoT World Today.

Key Takeaways from This Article:

- As the global economy stalls, manufacturers have an opportunity to plot a future course.

- Smart manufacturing programs have gained in popularity, but broad-based support for them remains elusive.

- Organizations seeking to become data-driven should know the limits of their data-gathering capability.

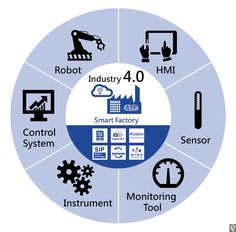

Experts are divided when it comes to recommending a north-star metric to guide manufacturers through these times of crisis and beyond. Davis points to the Industry 4.0 philosophy, which is a German smart manufacturing framework that integrates approaches such as lean manufacturing with supporting technologies such as the Internet of Things to cloud computing to artificial intelligence. “It is far more than just technology,” Davis said.

“Industry 4.0 does not have to be technically complex or expensive,” Davis said. “It starts simply with a focus on data to make better decisions.” “Becoming increasingly data-driven seems like a very cost-effective way to make the next stage in performance,” Tay said.

Industry 4.0 does not have to be technically complex or expensive,” Davis said. “It starts simply with a focus on data to make better decisions.” “Becoming increasingly data-driven seems like a very cost-effective way to make the next stage in performance,” Tay said.

For the full article on IoT World Today click here.