StilFold sells its first ‘industrial origami’ metal-folding machine to USA

Manufacturing startup StilFold has sold its first “industrial origami” metal-folding machine to industry, in a deal with Georgia Tech’s School of Civil and Environmental Engineering in the USA.

Studies suggest manufacturing accounts for more than half of the total environmental impact of the US economy. Stockholm-based StilFold is pioneering the use of curve folding and robotics to build things more sustainably.

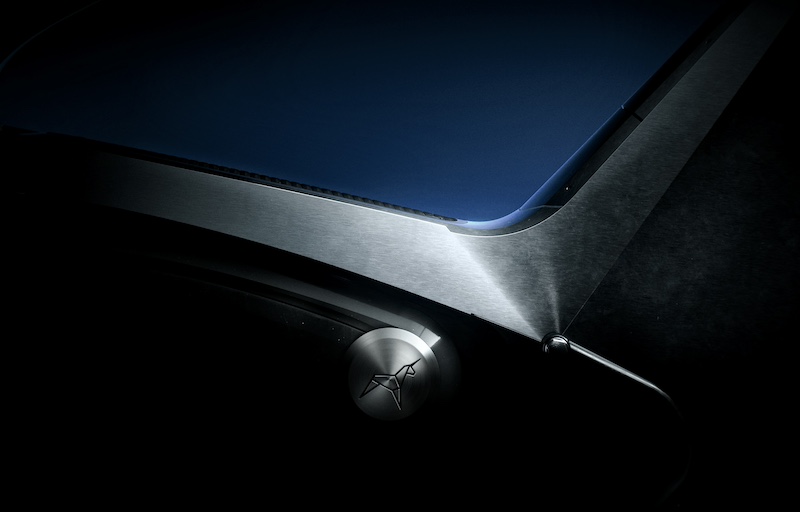

The company has created groundbreaking technology which involves the use of a specialist robotic cell and computational design software to fold flat sheet metal over curves to create complex, light and sustainable new structures, using minimal component parts.

The technology is currently being used to build a lightweight electric motorcycle called the StilRide 1.

StilFold is also exploring how the tech could be used to build trains, cars, and even to construct things in outer space.

StilFold’s technology was patented earlier this year. Now, Georgia Tech will be the first organization to purchase the StilFold technology and use it outside of the StilFold workshop.

At Georgia Tech, the StilFold tooling will be used for education and innovation purposes, where students will be able to use the technology to design and build work on-site as part of Georgia Tech’s “Origami Engineering” programme.

StilFold is working in partnership with Georgia Tech to advance the programme and teach students how innovative approaches to manufacturing can streamline production processes, reduce costs and minimize engineers’ environmental impact.

Dr Lauren Stewart, of Georgia Tech’s School of Civil and Environmental Engineering, says: “We are really excited to be working with StilFold to provide our students with hands-on experience with advanced technology, cutting-edge structural engineering, and sustainable manufacturing.

As we delve deeper into StilFold as a manufacturing technology, it becomes increasingly promising. The technology delivers on all fronts from cost-effectiveness to environmental adaptation, which is a necessity in all future manufacturing.

Giving our students the opportunity to be at the forefront of this development is very gratifying.

Jonas Nyvang, CEO and co-founder at StilFold, says: “We’re incredibly excited to have reached this milestone where our technology is being taken overseas to be used in new contexts.

“We have designed StilFold to be flexible and adaptable. We want it to be used to build and bend things big and small.

“We hope it will be a catalyst that inspires future sustainable manufacturing innovation and drives a greener future for the sector.

“Research and development is an essential part of this mission, so working with Georgia Tech is really exciting for us.”

StilFold has been gearing up to make its patented manufacturing software and hardware available to designers, architects, manufacturers and engineers since it announced its plans to commercialize the technology in 2022.

In May 2023, StilFold was granted a Swedish patent that covers the core robotic hardware, as well as the company’s proprietary software which enables designers to create folding instructions for 3D shapes.

StilFold was this week also granted a European patent for its origami-inspired method for curve-folding, its StilFold robotics machine and its proprietary design software.