No post processing or surface finishing is required to produce air- and water-tight seals, grommets, and bladders.

September 22, 2022

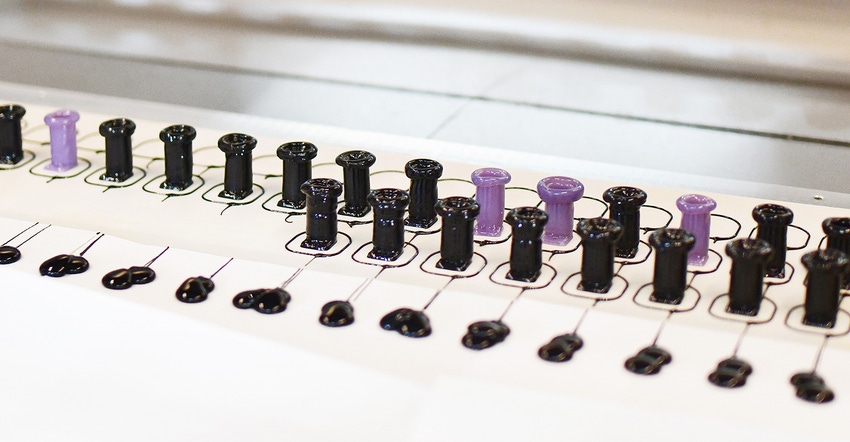

Smooth-Mode technology, developed by Chromatic 3D Materials, enables 3D printing of durable rubber parts with ultra-smooth surfaces at commercial volumes. High-quality polyurethane parts, such as seals, gaskets, grommets, and bladders, can now be 3D printed without post-processing requirements or surface finishing, said the company.

Sealing requires a smooth surface, but 3D-printed parts typically have layer lines or roughness. “We have developed a way to easily and cost-effectively 3D print products that are ultra-smooth without additional steps,” said Dr. Cora Leibig, Chromatic CEO and founder. “It’s a breakthrough for 3D printing those professional applications that must be air- and water-tight.”

Parts printed with Smooth-Mode technology have superior aesthetics as well as finer dimensional accuracy, claims the company. For example, products can be printed with precise uniform thickness at sub-millimeter scale, enabling the printing of elastomeric products that expand and contract.

To achieve this outcome, Chromatic’s team of additive manufacturing experts began by fine-tuning the viscosity and surface tension of the company’s printable thermoset polyurethane materials. “We developed a way to go beyond simply applying our reaction technology to fused deposition modeling (FDM). Smooth-Mode uses chemistry to create an ultra-bonded and smooth part. We believe this printing technique delivers the world’s smoothest printing along the Z, or height, axis,” explained Dr. Bart Engendahl, Chromatic’s managing director in Germany, where the company was founded in 2016. Its US headquarters is in Golden Valley, MN, a suburb of Minneapolis.

Industrial manufacturers can take advantage of Smooth-Mode with Chromatic’s Reactive Extrusion Additive Manufacturing (RX-AM) platform, which encompasses materials, software, and hardware for deposition printing with reactive chemistry. Printable polyurethanes are available in Shore A hardnesses ranging from 50 to 90; custom grades with varying colors, hardnesses, and special properties are also offered. The platform is designed for 3D printing at commercial volumes.

The technology is suitable for applications in transportation, industrial seals and gaskets, textiles, medical devices, and defense.

You May Also Like