Zebra survey shows eight-in-10 millennials expect more transparency in automotive manufacturing

Study reveals high demand for knowing the origin and sustainability level of materials and automotive parts as well as receiving an end-to-end view of the manufacturing process

Latest Material Handling News

Registration open for Pack Expo International 2024 Walmart chooses Swisslog AS/RS and software for third milk processing facility NetLogistik partners with Vuzix subsidiary Moviynt to offer mobility solutions for warehouses Lucas Watson appointed CSO for Körber’s Parcel Logistics business in North America Hyster recognizes Dealers of Distinction for 2023 More NewsZebra Technologies Corporation, a provider of mobile devices, data capture solutions, robotics and other hardware and software offerings that digitize and automate workflows, today released the findings of its Automotive Ecosystem Vision Study which confirmed automotive manufacturers are under pressure to accommodate growing consumer demands for sustainability and transparency throughout the manufacturing process, and fleet managers’ need for the digitization of operations and supply chain.

Despite a fluctuating economy, automotive manufacturers are ready to invest in technology innovation as seven-in-10 expect to increase their tech spend and six-in-10 plan to increase their manufacturing infrastructure spend in 2023, the research found.

Spanning multiple generations, consumers are a driving force behind automotive manufacturers’ acceleration to technology innovation as eight-in-10 say sustainability and eco-friendliness are key priorities in their vehicle purchase and lease decisions. Eighty-seven percent of Millennials prioritize sustainability in their vehicles followed closely by 78% of Gen Xers and 76% of Baby Boomers.

Consumers are also driving the growing emphasis on personalization – the ability to customize a vehicle to their liking. Nearly four-in-five consumers say personalization options factor into their decision to purchase a vehicle, and eight-in-10 fleet managers share these same requirements for sustainability and personalization. While nearly 80% of automotive industry decision-makers recognize consumers expect more sustainable and personalized vehicle options today, seven-in-10 concede it’s difficult to keep up with increasing customization demands. As a result, three-fourths of automotive manufacturers say a top priority is to build strategic partnerships with tech companies for their next generation of production.

“There’s no doubt the automotive manufacturing ecosystem is undergoing a seismic shift with huge hurdles to cross. This includes essentially running two distinct manufacturing processes – one for traditional gasoline/diesel vehicles and the other for next generation electric, hybrid and autonomous self-driving vehicles,” said Stephan Pottel, Automotive Industry Lead, Zebra Technologies. “The pressure to meet regulations, demands for sustainability as well as do more faster and provide real-time visibility throughout the supply chain is daunting. With the right strategic investments in technology, the automotive industry can meet and even surpass these expectations and better serve their customers.”

The survey results also reveal stronger preference to purchase electric vehicles (EV) in the future with more than half of consumers indicating their future preference is for a hybrid electric vehicle (HEV). However, navigating this increasing demand for EVs comes with challenges as 68% of automotive industry decision-makers say they are under high pressure to produce next generation (i.e., electric) vehicles, and 75% of them are under high pressure to deliver products that are more eco-friendly, sustainable and safer for the environment.

Data and information transparency is highly important to consumers and fleet managers alike, and they’re seeking more visibility into the automotive ecosystem. When considering a vehicle for purchase or lease, 81% of consumers and 86% of fleet managers indicate they want to understand the origin of materials and parts on their vehicle. Millennials lead the way for more transparency in automotive manufacturing as eight-in-10 say it’s important to have access to manufacturer information along with knowing if source materials and parts are sustainable and understanding how the vehicle is manufactured from end-to-end.

Beyond gaining greater visibility into the automotive manufacturing process, once they have their vehicles, 88% of consumers and 86% of fleet managers want to understand how the data from their vehicles will be used by the automotive ecosystem. After a vehicle purchase, 83% of consumers and 84% of fleet managers expect ownership and control of the data their vehicle generates.

A majority of consumers and fleet managers (80%) want end-to-end visibility during the manufacturing process. However, only about three-in-10 automotive industry decision-makers say they will prioritize connecting real-time data systems to enable a holistic view of operations and increase visibility across production and throughout the supply chain over the next five years.

About one-third of original equipment manufacturers (OEMs) said autonomous mobile robots (AMRs), RFID, rugged handheld mobile computers and scanners as well as industrial machine vision will improve supply chain management while about one-third of suppliers cite mobile barcode label/thermal printers, wearable computers and location technology as the technologies to do so.

Overall, seven-in-10 automotive industry decision-makers agree digital transformation is a strategic priority for their organization. In the next five years, they anticipate expanding their use of technology with 47% focused on additive manufacturing/3D printing and 45% on supply chain planning solutions.

Article Topics

Zebra Technologies News & Resources

Zebra Technologies introduces wearable computers Data Capture: Bar coding’s new friends Retail distribution closes in on the customer Automatic data capture (ADC): Accelerating the process Van Meter: Saving space while increasing throughput Van Meter optimizes with vertical lift modules (VLMs) Zebra study: nearly six in 10 warehouse leaders plan to deploy RFID by 2028 More Zebra TechnologiesLatest in Materials Handling

Registration open for Pack Expo International 2024 Walmart chooses Swisslog AS/RS and software for third milk processing facility NetLogistik partners with Vuzix subsidiary Moviynt to offer mobility solutions for warehouses Materials Handling Robotics: The new world of heterogeneous robotic integration BSLBATT is looking for new distributors and resellers worldwide Lucas Watson appointed CSO for Körber’s Parcel Logistics business in North America Hyster recognizes Dealers of Distinction for 2023 More Materials HandlingSubscribe to Materials Handling Magazine

Find out what the world's most innovative companies are doing to improve productivity in their plants and distribution centers.

Start your FREE subscription today.

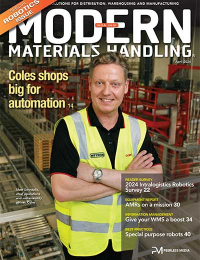

April 2024 Modern Materials Handling

Latest Resources