Though it’s been discussed for years, and its capabilities are increasingly being incorporated into automation hardware and software of all types, artificial intelligence (AI) remains a bit of a mystery to many end users. The mystery is not necessarily created by a lack of understanding about AI, it’s the application of the technology that raises many questions since it can be used for everything from machine control to cloud-based data analytics.

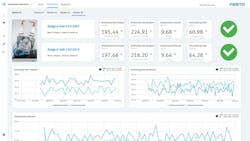

To demonstrate how AI can be used in CPG (consumer packaged goods) production operations, Festo is introducing its Festo Automation Experience (AX) at PACK EXPO International (Booth N-6213). By using advanced analytics, Festo AX maps data to learn a component, machine, product, or system’s healthy state and provide information for the correction of anomalies when data begins trending out of the normal range. Festo AX can be operated directly on equipment at the edge of the network, on data center servers for general on-premises applications, or in the cloud.

According to Festo, Festo AX can lower waste by more than 50%, reduce product rejection costs by more than 45%, increase machine availability by more than 25%, and reduce unplanned downtime by more than 20%.

While Festo AX, of course, works with any Festo components, its use of common industry communications and networking technologies such as OPC UA and MQTT means that it can also be integrated with third-party components and machines. For example, linking Festo AX to the Festo Smartenance or a third-party maintenance management program can extend Festo AX’s effectiveness by providing the packaging maintenance department with a tool to help them keep the machines making quality products at optimum energy consumption.

Pilot projects using Festo AX typically take six to 12 weeks to complete. Once the business case has been made, physical rollout to machines, lines, and factories can be accomplished in three to six months.