Benefits of Using Sculpteo 3D Printing

In a world where innovation drives progress, 3D printing has emerged as a game-changing technology. Sculpteo is reshaping industries from aerospace and healthcare, to fashion and automotive.

Among the many service providers, Sculpteo is a pioneer. They offer a wide array of cutting-edge solutions to individuals and businesses alike.

We’ll explore the multitude of benefits it brings to the table. These benefits range from rapid prototyping and cost-efficiency to customization and sustainability.

Sculpteo offers 3D printing services for your business. They’re poised to revolutionize how we design, create, and manufacture in the 21st century.

Join us on a journey through the world of 3D printing, discovering why Sculpteo is at the forefront of this transformative technology.

What is 3D Printing?

Imagine creating an object slice by slice, where each slice is skinny, 3D printing is different from traditional manufacturing.

It doesn’t involve cutting or removing material, instead, it creates complex three-dimensional objects with great precision. It enables individuals and industries to produce custom-designed items with high accuracy.

Advantages of Sculpteo 3D Printing

The benefits of 3D printing span various industries, it redefines design and manufacturing, offering advantages like rapid prototyping and cost-efficiency. This transformative technology allows for unprecedented design flexibility and sustainability.

Faster than Conventional Manufacturing

Sculpteo revolutionizes the speed of design and production, what used to take months can now be accomplished in a matter of days. Gone are the days of relying on warehouses and costly machinery.

Sculpteo allows for the rapid creation of complex parts, it slashes lead times for outsourcing manufacturing and eliminates order constraints.

A Cheaper Alternative

It’s much cheaper in certain cases, for example for small quantities, than CNC and injection molding, which are traditional methods, it does this by minimizing trial and error in design.

Moreover, it eliminates the need for expensive machinery and reduces labor expenses. Additionally, with Sculpteo, you create products from scratch rather than subtracting material, subsequently reducing waste.

Wide Range of Materials

This industry offers many technologies and materials to choose from, each of these technologies is tailored to specific project requirements. Whether you’re considering FDM, SLS, Binder Jetting, or other options.

There’s technology suited to your needs and identifying your project’s specific demands is crucial to making the right choice. Are you looking for durability, flexibility, heat resistance, or food compatibility?

These are just a few factors to consider when selecting the ideal technology and material. To fully enjoy 3D printing, identifying your specific needs and requirements are crucial.

Ergonomics

3D printing offers unparalleled design freedom, it can create intricate designs and geometries, which are impossible with traditional methods. Examples include parts within parts and hollow cavities within solid structures.

Even those with minimal CAD knowledge can create and edit designs with ease. Addtionally, many materials can be used in a single object, this further allows for a blend of mechanical properties and textures.

Easy Quality Check

3D printing accelerates the product development cycle, people can create and test physical prototypes to get feedback from the consumers. This iterative production process ensures continual enhancement in design and high-quality parts.

Consistency

3D printing ensures consistency by manufacturing parts and enabling real-time fault detection, this results in less waste and fewer failed parts during production. Testing product prototypes before production reduces expensive errors, resulting in higher-quality products.

Accessibility

With Sculpteo, 3D printing is automated and requires minimal extra staff, this makes it more accessible and cost-efficient than conventional manufacturing processes.

The benefits of accessibility and sustainability make it an attractive choice for businesses, if they want to innovate and reduce environmental impact.

Transformative Technology

Sculpteo’s 3D printing services are at the forefront of transformative technology, they offer rapid production, cost-efficiency, and unmatched design flexibility.

With Sculpteo, you can create complex objects efficiently. Among other things Sculpteo strives for sustainable practices which they always try to improve upon.

They help reduce waste and costs with their innovative approach, making 3D printing accessible and consistent while accelerating product development. Sculpteo is leading the way in reshaping how we design, create, and manufacture in the 21st century.

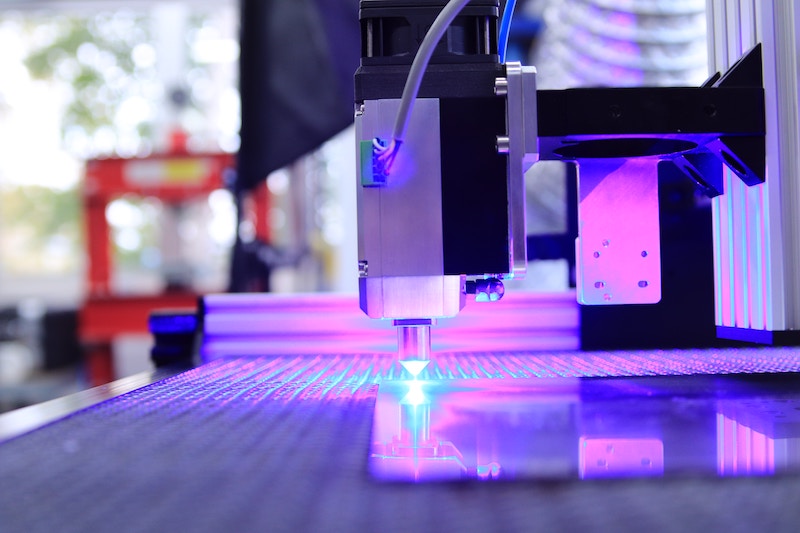

Main image by Opt Lasers on Unsplash