JEC Composites Innovation Awards: Finalists in Aerospace Parts Category

Aerospace parts category features entries from Fuko, ATG Europe, and Sogeclair Equipment.

January 22, 2024

At a Glance

- Helicopter landing gear blends carbon- and flax-fiber-reinforced composites

- Single-shot process for CFRP satellite central tubes

- Thermoplastic composite door integrates overmolded parts

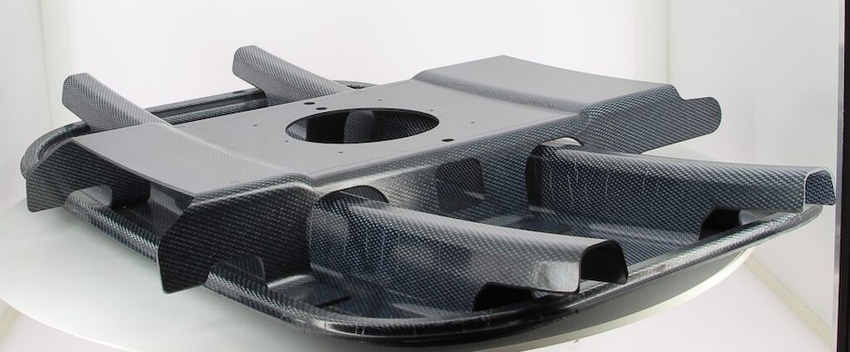

BioGear

Company: Fuko srl (Italy)

Partner: Turtle srl (Italy)

Image courtesy of Fuko

Description: BioGear is a helicopter landing gear blending carbon- and flax-fiber-reinforced composites, achieving a 60% weight reduction over traditional metal counterparts. BioGear not only enhances emergency landing response but also prioritizes both efficiency and environmental impact.

BioGear combines recycled carbon fiber and flax-based composites, weighing only 6.9kg (40% of the original). Meeting CS.27 specifications and exceeding emergency landing requirements (CS 27.727), BioGear also outperforms traditional metallic counterparts.

Prioritizing sustainability, recycled carbon fibers reduce environmental impact, transitioning to a cradle-to-cradle approach. Flax fibers offer advantages of low environmental impact, density reduction, and vibration dampening. BioGear aims for lightweight design, enhanced energy absorption, and minimal drag resistance through meticulously studied airfoil cross-sections using CFD simulations while keeping an eye on manufacturability through autoclave molding.

Key benefits

Landing skid weight reduced by 60%

Massive CO2 reduction confirmed by cradle-to-grave analysis

Minimized drag resistance thanks to airfoil shape optimization

Optimized design employs recycled carbon fibers with no safety issues

Intercalation of flax fibers in the composite reduces vibrations

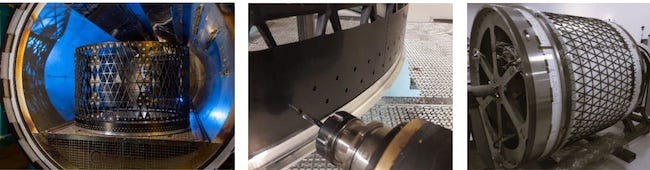

CFRP lattice satellite central tube

Company: ATG Europe (Netherlands)

Partner: ÉireComposites Teo (Ireland)

Image courtesy of ATG Europe

Description: ATG Europe has developed a one-shot manufacturing process for uninterrupted prepreg fiber-placed lattice structures that aim to replace current satellite central tube designs. These cylindrical lattice structures offer optimal structural functionality at a reduced mass. This innovation included the design, development, and manufacture of a fully representative carbon-fiber-reinforced plastic (CFRP) lattice central tube based on requirements for the European Space Agency’s Plato satellite, including all necessary interface zones. Thermoset pre-preg carbon-fiber tows and patches were manually laid-up onto a mandrel and consolidated and cured in an autoclave in a single step to form one integral part. The primary interface to the launcher structure was provided by a one-piece aluminum interface ring, which was integrated with the lattice cylinder through a hybrid joint.

Key benefits

One-shot manufacturing process

Structural efficiency and significant mass savings

Uninterrupted pre-preg fibers leading to optimized structural performance

High specific stiffness

Reduced manufacturing time and cost

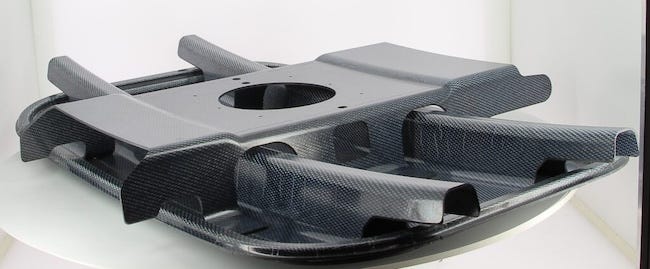

Thermoplastic composite door

Company: Sogeclair Equipment (France)

Partner: Airbus Atlantic (France)

Image courtesy of Sogeclair Equipment

Description: Sogeclair Equipment, formerly known as Aviacomp, has developed an aeronautic door, featuring a complex stamping shape and advanced welding, that is fabricated from a thermoplastic composite. With integrated overmolded parts and an optimized design, the solution significantly reduces weight and assembly time using composite materials and induction welding.

Thermoplastic polyphenylene sulfide (PPS) and carbon-fiber fabric are processed via injection molding. A single material is used to facilitate recycling. Processes include thermostamping for shaping, waterjet cutting, induction welding for function integration and assembly, and injection overmolding.

Key benefits

Reduced environmental impact

40% weight reduction and 20% cost saving

Accelerated manufacturing

No fixation needed thanks to induction welding

About the Author(s)

You May Also Like