While we think of robots as flexible automation, the reality is they just follow preprogrammed paths. Reliable, consistent operation requires a fixed and predictable work environment, and that limits how and where they can be used. AI for industrial robots promises to change that. Here’s how.

The evolution of robotics in manufacturing

Industrial robots have been around for more than seven decades. The first application, in 1959, was in a diecasting operation. This provides an excellent example of robots taking on dirty, dangerous and difficult tasks.

Ten years later came five- and six-axis electrically powered robots with a motor at each joint. A sophisticated controller optimized the joint kinematics to move the tool or gripper to the required location. Other forms of robots use only three of four axes, moving in cartesian (x,y,z) coordinates with perhaps a single rotary axis.

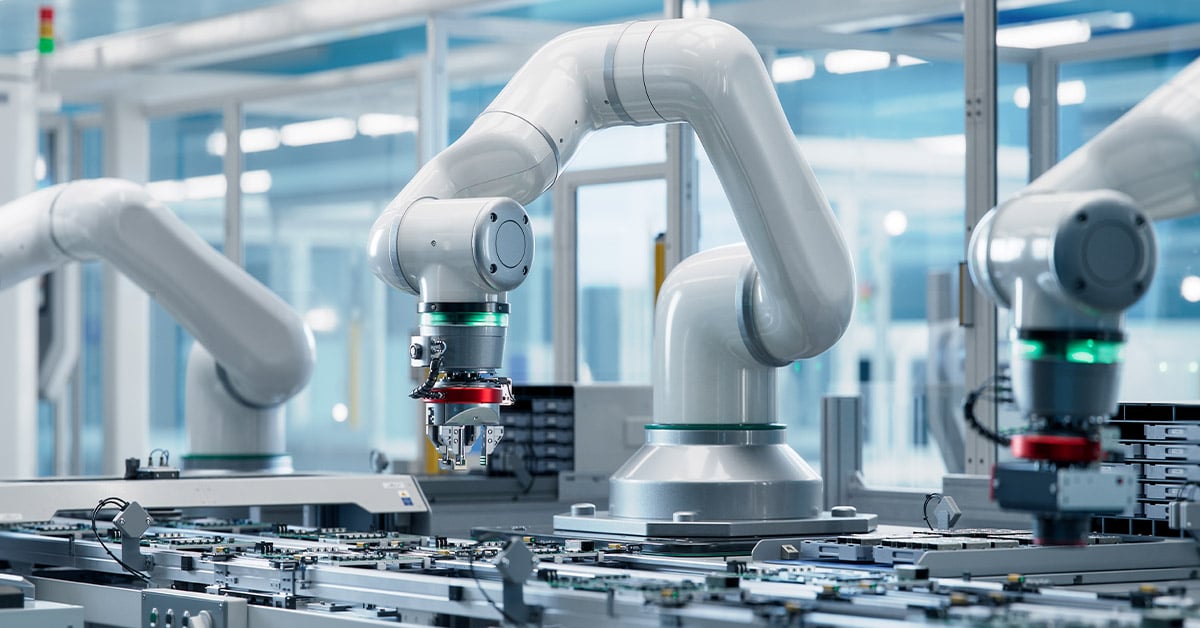

The most recent advance in robotics for manufacturing is the development of the collaborative robot, or “cobot” for short. This addresses one of the biggest limitations of conventional robots: the complex systems needed to ensure the safety of people working nearby or simply passing by the robot.

Collaborative robots in manufacturing are engineered with safety systems that prevent them from injuring anyone within its work envelope. This can be done by:

- Monitoring and controlling speed and separation

- Stop-state monitoring

- Limits on power and force

- Hand guiding

Cobots still require risk assessments before being put into service, because the tool or gripper could be doing something potentially hazardous. In most applications though, they need far less guarding than conventional robots. Eliminating the need for large and expensive safety cells, which in term mandate complex systems for moving work in and out of the cell, is one of their biggest benefits.

How AI-powered robots are improving manufacturing

Manufacturing is undergoing a dramatic transformation. Often referred to as Industry 4.0, this fourth industrial revolution is about digitization, “smart” sensors and cyber-physical systems such as digital twins. A key driver is the tremendous advance in computational capabilities currently underway.

In this world of “smart” factories opportunities for artificial intelligence in manufacturing are only just starting to emerge, but robotics appears one of the most impactful. Despite their immense utility in automated manufacturing, robots and cobots have some limitations:

- Parts must be presented in a consistent and predictable manner (vision guidance can help with picking parts from a bin but the bin must be placed consistently).

- The programmer must anticipate every possible event and ensure the robot can react appropriately.

Using AI with robotics provides a solution. No longer need the work environment be highly structured: Instead, the robot, aided by cameras and other sensors, can find its way around. Four ways in which this improves manufacturing are:

- Enables shorter production runs (because setup and programming time is reduced)

- Reduces implementation cost and complexity

- Enables new applications previously not feasible for robotic automation

- Reduces cell downtime due to teach pendant programming

Ways manufacturing robots utilize AI

The ability to learn and adapt to changes in the environment requires the robot to sense what’s going on in its work envelope. This is done mainly with cameras, although scanners and 3D sensors are also used. AI tools then analyze the images or other signals acquired and use this to determine what the robot should do.

AI is applied to industrial robots for three types of application:

- Environment perception using sensors & tactile feedback: This could be to detect the presence of part trays or pallets of material, sense loads or adapt to changes in the friction of surfaces being touched or picked up.

- Data-driven computation and execution: Path planning is a major challenge in many robot applications, especially when approach angle and direction affect how the process is performed or part design precludes some tool/gripper orientations. Rather than a programmer spending a lot of time attempting to find the best route, and likely still not achieving the optimal solution, AI can quickly evaluate alternatives and determine the best path.

- Integration into automated systems: Robot cells use multiple sensors to detect presence, position, orientation and other parameters, all of which must be handled by the cell PLC and robot controller. Despite this, a robot will still sometimes fail to grasp or place a part, simply because it’s not exactly where it was expected. A robot powered by AI has the ability to recognize variation, in the cell, workpiece or tool, and adjust accordingly.

Examples of manufacturing robotics & artificial intelligence

While robots and increasingly cobots are staples of industrial automation, examples of robotics in artificial intelligence are still in short supply. However, work in academia, and some pioneering industrial applications, suggest at least four classes of application.

- Cobots: This new generation of industrial robots is designed to work alongside and even in cooperation with human operators. Adding AI to the mix enhances the ability of the cobot to work with a human. For example, in assembly, it can wait until the human has completed a complex task like insertion before adding the next component.

- Industrial assembly: Orientation and fit have so far proven difficult aspects of assembly work to automate. However, AI gives robots greatly enhanced capabilities to judge position and orientation, enabling performance of complex tasks like meshing gears. Assessing quality of fit is another area where human judgment has been needed. With AI though, a robot can acquire information about how tight or loose an assembly feels through attached sensors, and either change parts or make adjustments as needed.

- Piece picking: Grasping and retrieving randomly oriented and overlapping parts from a bin is one of the hardest problems in robotics. AI will let a robotic system learn the most effective picking strategies for particular sizes, shapes, weights and even textures of parts, thereby increasing picking speed and reliability.

- Inspection: A robot carrying a camera can scan over a part to look for flaws such as scratches, chips and dents. Should suspected flaws be detected, the robot can move the camera closer and change orientation to obtain views from different positions before making a final good/no good decision.

How has robotics changed manufacturing technology?

By moving tools or parts along programmed paths through space, robots provide flexible motion. This enables automation of tasks such as machine tending, welding, dispensing, packing and palletizing. Not every manufacturer has been able to take advantage of these capabilities though. Programming, safety challenges, and integration complexity have limited their use to higher volume production situations. That’s changing.

Cobots have reduced implementation costs, and now, with AI industrial robots need less programming and have less stringent requirements for cell layout and part positioning. They can even accommodate variation in the parts being grasped or placed.

This is putting robotic automation in reach of smaller manufacturers and those with more diverse product lineups. With AI, these companies won’t need to tie up programming resources or production equipment while new programs are written and tested. Instead, with little more than the press of a button they’ll be ready to go.

AI with industrial robots will make the vision of flexible automation a reality.

Maintenance services for busy manufacturers

Over the years industrial robots have proven extremely reliable. Their complete cells are complex though and can need a range of maintenance services. At ATS, we’re experienced with all aspects of industrial automation, including advanced robotics, and we can provide the maintenance services and support needed. Contact us to learn more.