Metal additive manufacturing company Velo3D has partnered with PWR Advanced Cooling Technology to qualify Constellium’s Aheadd CP1 aluminium alloy for use in Sapphire printers.

PWR will use the alloy to manufacture compact and lightweight head exchangers for Formula 1, along with a variety of other components for their high-performance customers.

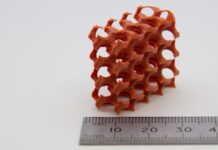

Aheadd CP1 is being qualified to print in 100-micron layers to provide customers with a balance between finished part performance and system throughput, Velo3D said in a media release.

The 100-micron layer print will be offered alongside the standard 50-micron layer thickness that all of Velo3D’s printers use.

Fédération Internationale de l’Automobile (FIA), the governing body overseeing Formula 1 and other motorsports, has approved the Aheadd CP1 alloy for use in Formula 1 cars beginning in the 2024 season.

Zachary Detweiler, vice president of technology at Velo3D, said Aheadd CP1 is the first alloy qualified in the company’s Augsburg, Germany European Technology Centre.

“Our American and European teams are both adept at creating scalable solutions for metal AM materials and we encourage companies who need customized material development for their applications to contact us about their specific requirements,” Detweiler said.

Aheadd CP1 is an aluminum, zirconium, iron alloy designed for laser powder bed fusion printers. The material is thermally stable up to 300 degrees Celsius, is capable of corrosion resistance and is highly isotropic.

“Aheadd® CP1 is a fantastic addition to our additive manufacturing services and Velo3D’s unparalleled print capabilities coupled with PWR’s brazed fin technology creates a unique performance differentiator for our customers,” said Mark Booker, technical project manager at PWR. “Our goal is to give our racing customers an unfair advantage on the track and we look forward to seeing these teams win using new parts manufactured by PWR.”

For the past 20 years, PWR has been working with customers in F1, NASCAR, V8 Supercars, Deutsche Tourenwagen Masters, and other motorsports categories, providing them with high-performance aluminium radiators, intercoolers, oil coolers, and other finished parts.

The company also serves customers in the energy, defence, and aerospace industries.