Exploring Hydraulic Cylinder Types: Single vs Double Acting. Tie Rod, Welded, and Telescopic.

Single vs Double Acting Cylinders.

Single-Acting Cylinders

A single-acting hydraulic cylinder has only one port at the end of the cylinder.

A single-acting hydraulic cylinder has only one port at the end of the cylinder.

Hydraulic fluid is moved into the cylinder through the port, and the hydraulic pressure created extends the piston rod forward in one direction, known as the linear force.

When the pressure is released, a spring or the weight of the load returns the piston to its original position.

The components of a single-acting cylinder include the cylinder body, a piston, a piston rod, and a port for the hydraulic fluid.

Single-acting cylinders are reliable and cost-effective, suitable for use in various applications where space is limited.

Advantages of Single-Acting Cylinders:

Cost-Effective: Single-acting cylinders are generally less expensive than double-acting cylinders, as they require fewer hydraulic components and less complex control systems.

The Simplicity of Design: Single-acting cylinders have a simpler design and are easier to install and maintain than more complex cylinders.

Single-Acting Hydraulic Cylinder Applications:

Lifting Equipment: Single-acting cylinders are commonly used in lifting equipment, such as scissor lifts and hydraulic jacks.

Dump Trucks: Single-acting cylinders are used in dump trucks to raise and lower the trailer bed.

A double-acting hydraulic cylinder has two ports, one at each end of the cylinder.

Double-Acting Cylinders

A double-acting hydraulic cylinder has two ports, one at each end of the cylinder and uses hydraulic pressure to move the piston rod in two directions.

A linear force is created from hydraulic fluid being moved into one of the ports, pushing the piston in one direction. With double-acting cylinders, to reverse the force hydraulic fluid is moved into the opposite port pushing the piston back to its original position.

Double-acting cylinders allow for greater control over the movement of the load or workpiece as they use power instead of gravity to bring the cylinder back down.

Double-acting hydraulic cylinders are the most common type of hydraulic cylinder used in heavy-duty manufacturing industries.

Advantages of Double-Acting Cylinders:

Controlled Movement in Both Directions: Double-acting cylinders exert force in both directions, which allows for more accurate control over the movement of the load or workpiece.

Versatility and Adaptability: Double-acting cylinders can be used in a wide range of applications, from heavy machinery to manufacturing equipment.

Double-Acting Hydraulic Cylinder Applications:

Heavy Machinery and Construction Equipment:

Double-acting cylinders are commonly used when precise control over the movement of the load is needed such as in excavators, bulldozers and other heavy machinery, manufacturing equipment.

Hydraulic Cylinder Designs.

There are three main hydraulic cylinder designs currently used in industrial settings. As with the cylinder option, the right design will depend on the application in which the hydraulic cylinder is applied.

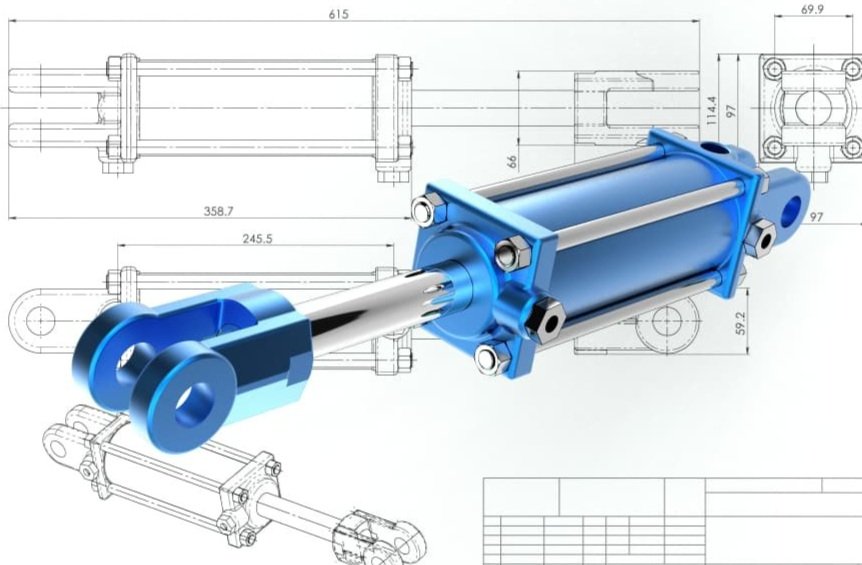

Tie-Rod Cylinders.

Tie-rod cylinders are manufactured using a hydraulic cylinder tube, a piston rod, and end caps that are connected by threaded tie rods.

Tie-rod cylinders are manufactured using a hydraulic cylinder tube, a piston rod, and end caps that are connected by threaded tie rods. The tie rods run the entire length of the cylinder tube and through holes in the end caps. Each rod is secured with a nut to hold the end cap to the cylinder barrel.

Hydraulic fluid is used to power the piston, allowing for reliable and precise control of linear motion. Tie rod hydraulic cylinders are used in a variety of heavy-duty industries, from construction equipment to manufacturing, to provide controlled power for lifting, pushing, and pulling.

Advantages of Tie-rod Cylinders:

Ease of Maintenance: Tie-rod cylinders are relatively easy to maintain and repair, as they can be disassembled easily by removing the tie rods.

Cost-Effective Solution: Tie-rod cylinders are generally less expensive than other types of hydraulic cylinders, such as welded cylinders.

Common applications for tie-rod cylinders include:

Mobile Equipment: Tie-rod cylinders are used in mobile equipment such as agricultural equipment, cranes, and construction equipment.

Material Handling: Tie-rod cylinders are used in material handling equipment, such as conveyor systems and lift trucks, to control the movement of materials.

Mining and Extraction: Tie-rod cylinders are used in mining and extraction equipment, such as loaders and excavators, to provide reliable and efficient linear motion control.

Welded Cylinders.

Welded hydraulic cylinders are manufactured by welding the barrel to both end caps.

Welded hydraulic cylinders are manufactured by welding the barrel to both end caps. The mounts and other cylinder fittings are also welded to the end cap with this design.

They are designed to be more durable and resistant to leaks in harsh environments and generally have longer life cycles than tie-rod cylinders.

Welded hydraulic cylinders have a compact, lightweight design with higher pressure capabilities and are used in a wide range of mobile equipment where heavy loads are involved such as in the construction and industrial machinery sectors.

Advantages of Welded Cylinders:

Greater Strength and Durability: Welded cylinders are designed to be more durable than tie-rod cylinders. They are less likely to leak and can handle higher pressure and heavier loads.

Compact and Lightweight Design: Welded cylinders are often smaller than tie-rod cylinders, which makes them a good choice for applications where space is limited.

Common applications for welded cylinders include:

Construction Equipment: Welded cylinders are commonly used in construction equipment such as excavators, bulldozers, and cranes.

Agricultural Equipment: Welded cylinders are used in farm equipment such as tractors and harvesters to lift and move heavy loads.

Mining Equipment: Welded cylinders are used in mining equipment such as hydraulic shovels and excavators to move earth and rocks.

Telescopic Cylinders.

Telescopic Cylinders consist of multiple nested barrels of varying diameters.

Telescopic cylinders, also known as multistage hydraulic cylinders, are a type of hydraulic cylinder that consists of multiple nested barrels of varying diameters, which extend and retract. Telescopic cylinders are designed to provide an extended range of motion within a single cylinder, providing a longer stroke than other types of cylinders.

Telescopic cylinders are used to lift, move, and position loads of all sizes, from large industrial components to the smallest agricultural tools.

They can be manufactured in single-acting or double-acting options.

Advantages of Telescopic Cylinders:

Longer Stroke Length: Telescopic cylinders can provide a much longer stroke length than other cylinders, making them ideal for applications with a longer reach.

Space-Saving Design: The nested design of telescopic cylinders allows them to be more compact than other types of cylinders, ideal for installation where space is an issue or limited.

Increased Flexibility: Telescopic cylinders can be customized to fit a wide range of applications, with different numbers of stages and different stroke lengths.

Common applications for telescopic cylinders include:

Dump Trucks: Dump trucks commonly use telescopic cylinders to lift and lower the truck bed for dumping materials.

Cranes: Telescopic cylinders are used in cranes to extend the boom and lift heavy loads.

Excavators: Excavators use telescopic cylinders to extend the boom and arm for digging and moving earth.

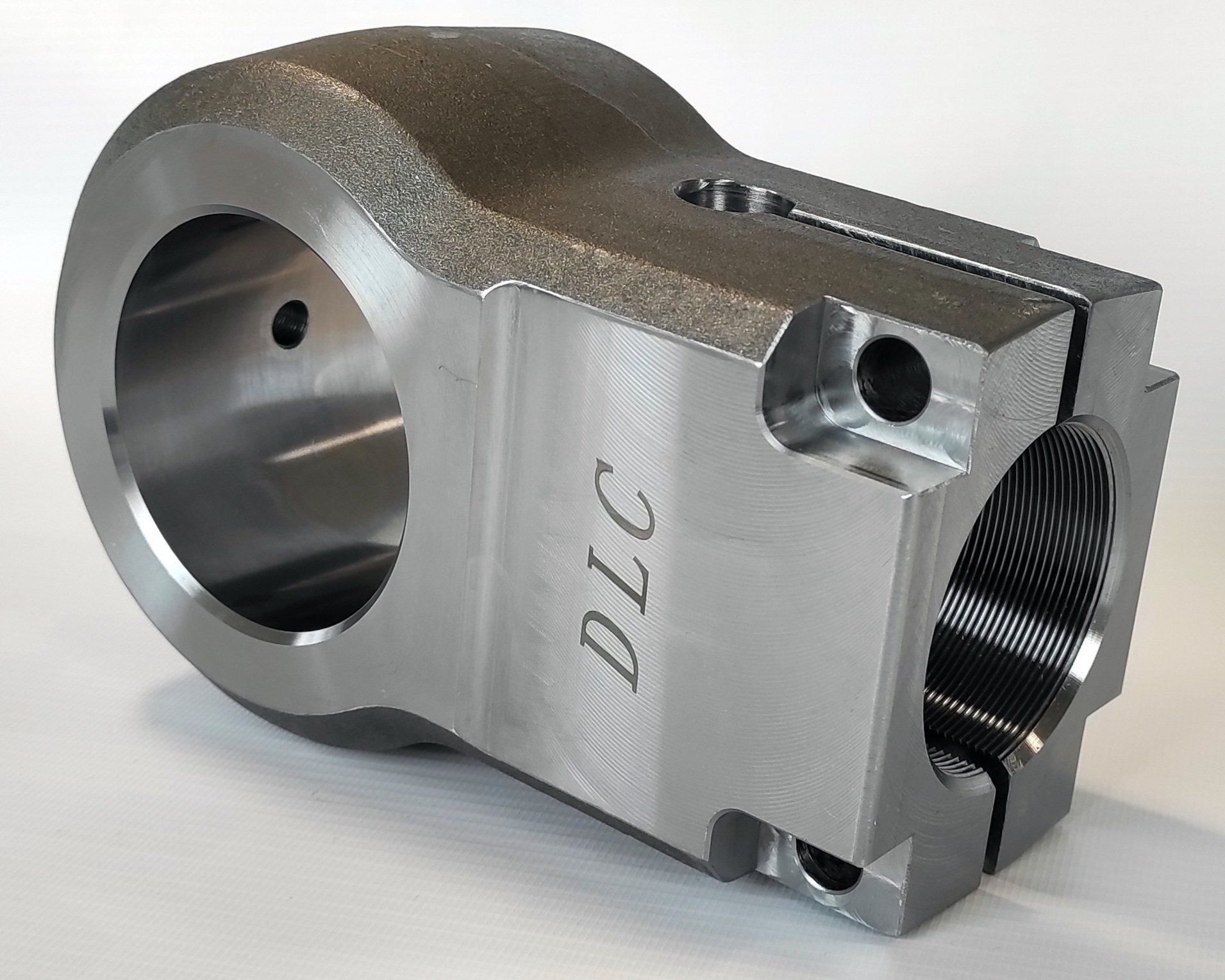

Donlouco: Custom Hydraulic Components.

Quality Components for Hydraulic Cylinders

Donlouco Ireland Ltd supplies parts to some of the most established hydraulic cylinder manufacturers in Europe.

With our extensive experience in the manufacture and supply of hydraulic components out of our facilities in the Far East, we assist our customers in streamlining their production processes, reducing costs, and improving part quality.

We supply you with highly complex CNC machined parts and forgings with full quality and material certifications.