Victoria-based additive manufacturing company SPEE3D is delivering its cold-spray metal 3D printing technology XSPEE3D printer to the British Army to boost its unplanned repair capabilities.

The UK service also signed a two-year contract to work with SPEE3D, which will involve delivering training courses and collaborating with the British Army’s Royal Electrical and Mechanical Engineers.

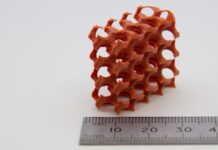

The Australian company’s XSPEE3D is capable of quickly producing parts from popular metal alloys, allowing the defence sector to address real-time needs. The printer is fully transportable as a standard shipping container, enabling it to deliver on-demand manufacturing.

With the solution, the customer will be able to manufacture and finish parts within hours instead of days for any vehicle or platform, from a range of materials, such as aluminium 6061, aluminium bronze, and copper.

Byron Kennedy, co-founder and CEO of SPEE3D, said the company has explored the impact of additive manufacturing to solve real supply chain problems by printing critical parts on demand in rough conditions.

“We are excited to be invited by the British Army to work closely together and bring our latest printer XSPEE3D to the field, offering a deployable and easy-to-use solution,” Kennedy said.

“The British Army chose to work with SPEE3D based on their successful track record of partnering with defence forces worldwide to provide the latest additive manufacturing solutions. We are proud to be a forward-thinking organization and are always exploring the latest technologies to solve the military’s most pressing supply chain issues, which SPEE3D’s technology helps us to solve,” said British Army Lieutenant Colonel Davidson Reith.

SPEE3D recently partnered with the British Army under the US Army’s Project Convergence program to demonstrate the impact of the company’s proprietary cold-spray technology on defence supply chains.

The company also worked with the Australian Army on several projects to test and validate metal 3D printing as a military capability for the field. The company trialled WarpSPEE3D thousands of kilometres into the harsh bushland of the Northern Territory’s remote areas.