The University of Texas at El Paso has joined a NASA-led initiative to use 3D printing techniques in order to produce rechargeable batteries from lunar and Martian regolith, the top layer of minerals that covers the moon’s and Mars’ surfaces.

The university said it received a $615,000 (AUD 912,000) grant from NASA as part of its $2.5 million (AUD 3.7 million) project including Youngstown State University (YSU), 3D printer firm Formlabs, and ICON, the private sector company now spearheading the NASA Mars Dune Alpha project, which aims to 3D-print future Mars dwellings.

By minimising payload weight and dead volume, the project’s long-term objective is to maximise the sustainability of astronauts’ upcoming lunar and Martian trips.

The use of locally available resources on the moon or Mars is critical for developing infrastructure such as habitation modules, power generation, and energy storage facilities.

“UTEP is a national leader in additive manufacturing for space applications,” said Kenith Meissner, PhD, dean of the UTEP College of Engineering.

“I congratulate the team of UTEP researchers involved in this important work. I am confident their work will add significant value to this project, getting us closer to a return to the moon and our first forays beyond,” the dean remarked.

Eric MacDonald, PhD, professor of aerospace and mechanical engineering and associate dean in the UTEP College of Engineering, said UTEP is a key participant in this NASA-led effort thanks to the university’s extensive background in additive manufacturing.

“UTEP’s reputation in 3D printing, material science and our state-of-the-art facilities were important factors in convincing our NASA partners to pursue this potentially transformative research – for space exploration but for terrestrial applications of batteries as well,” MacDonald explained.

While commercial lithium-ion batteries can be found in the majority of today’s applications, the university said manufacturing lithium-ion batteries from lunar and Martian soil is not a practical alternative because lithium is rare on the moon.

Because of the larger amount of sodium, the UTEP research team is currently focusing their efforts on sodium-ion battery chemistry for this project.

“This project with NASA is an opportunity to demonstrate UTEP’s expertise in both energy storage and 3D printing,” said Alexis Maurel, PhD, French Fulbright Scholar in the UTEP Department of Aerospace and Mechanical Engineering.

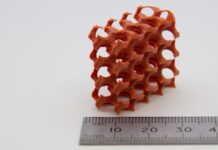

Maurel emphasised that additive manufacturing appears to be a novel technique for manufacturing shape-conformable batteries to support human operations in space and on the surface of the moon or Mars, where payload replenishment is not as readily available.

The UTEP team consists of Sreeprasad Sreenivasan, PhD, associate professor in the Department of Chemistry and Biochemistry, and Ana C. Martinez, PhD, a postdoctoral researcher in the Department of Aerospace and Mechanical Engineering.