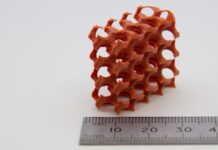

Microfabrication start-up Horizon Microtechnologies said that its in-house technology for template-based 3D microfabrication will help in the elimination of electro-static discharge (ESD) in applications, which would benefit from 3D printing by combining precision polymer micro-AM and ESD compliance.

In a press release, the company said that by incorporating additional material and functionality into the microstructure, typically through a post-build coating process, template-based 3D microfabrication takes advantage of the usefulness of polymer micro-AM-produced 3D microstructures for underserved areas of industry.

An example of the use of micro-AM conductive parts in ESD-prone areas is tooling for pick-and-place machines, which are automated assembly machines for putting tiny electronic components such as chips, resistors, and capacitors onto printed circuit boards at the positions they are needed at a very high speed, the company said.

Horizon added that optical and electrical components can also be positioned using pick-and-place machines onto larger assemblies, optical components such as bare laser diodes.

In both cases, the company said the components are extremely small, ESD sensitive, and will typically have at least two electrical contact points, each of which must be precisely placed in relation to whatever they are placed on.

“This requires a precise tool such as an end-effector or pick-and-place-head to move them. One common way of moving these components is to have a head that has a small orifice (smaller than the component) connected to a vacuum line,” said Andreas Frölich, founder and CEO of Horizon.

Frölich continued that micro-AM makes it simple to create the microscopic features, requisite tolerances, practically arbitrary shape, and internal channels, and our coating technique adds the conductivity required to eliminate ESD problems.

The CEO then explained the company can produce components with a controllably conductive surface coating and can also coat inside channels with multiple bends.

He added that the said production process enables the creation of extremely small, highly effective end-effectors for vacuum pick-and-place devices that are also sufficiently conductive to prevent electrostatic discharge.

“Antistatic properties and ESD safety also enable the use of our parts under conditions requiring spark-freedom and explosion-protection,” the CEO noted.

Horizon also pointed out that ESD can be an expensive problem in many industrial settings, and it is difficult to avoid because it can arise from seemingly insignificant processes.

To address this, the company stated that all materials and tools used in a manufacturing setting must have a minimum amount of conductivity as well as sufficient grounding to enable the controlled release of any possibly present electrostatic charges.