Industrial robot components market report: Anticipated 8.8 percent annual growth forecasted until 2027

October 17, 2023

By Manufacturing AUTOMATION

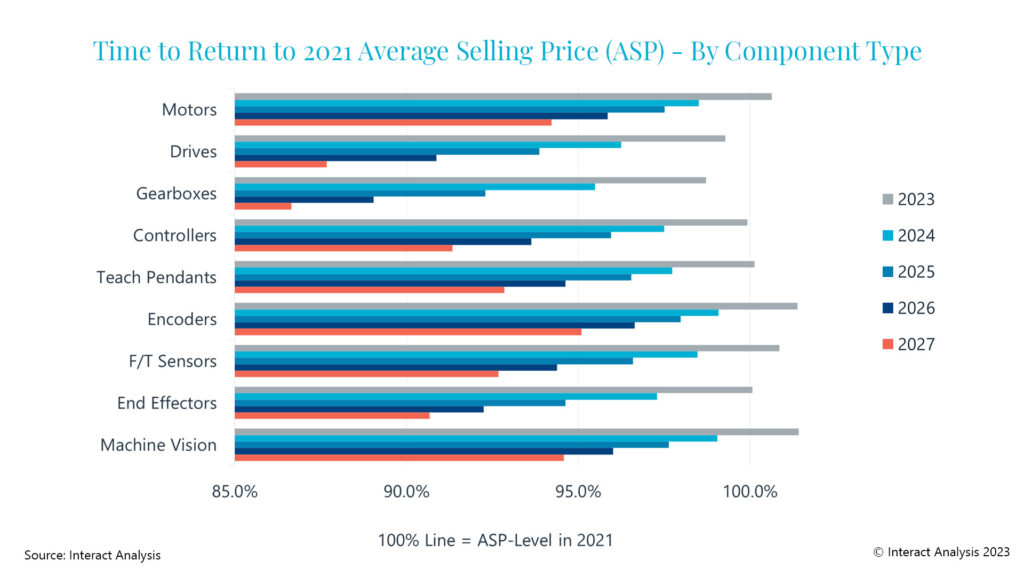

Average selling prices of industrial robot components are expected to fall, according to the Interact Analysis report. (Graph: Interact Analysis)

Average selling prices of industrial robot components are expected to fall, according to the Interact Analysis report. (Graph: Interact Analysis) A recent Interact Analysis report finds that the global market for key components used in industrial robots reached $12.1 billion in 2022. The 14.7 percent year-on-year increase was driven by the production of collaborative and SCARA robots. The report notes that the growth of the components market will likely slow down over time, as the robot market matures and stabilizes. Overall, the market for industrial robots components is expected to grow at a CAGR of 8.8 percent from 2022 to 2027.

The market size statistics include key components such as motors, servo drives, precision gearboxes, encoders and sensors, robot controllers, end effectors, machine vision hardware and teach pendants used in industrial robots and collaborative robots.

Demand changes in robot types

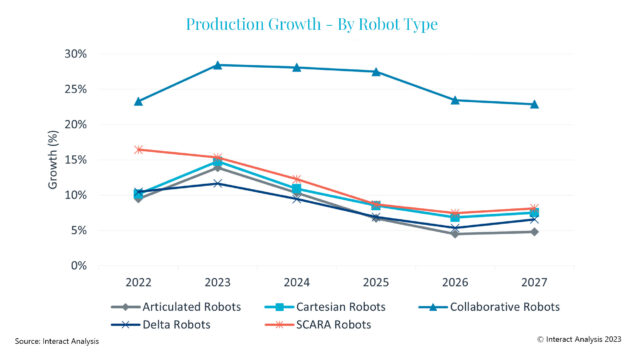

Interact Analysis, a global market research firm, finds in its report that demand for collaborative robots in industrial applications surged in the past two years and is expected to continue until 2027, driven by ease of use and increased human-machine collaboration. High-payload collaborative robots are growing faster, challenging traditional articulated robots.

Production of collaborative robots and SCARA robots is expected to grow the fastest, as per the report. (Graph: Interact Analysis)

SCARA robot production is set to have the second-highest CAGR among robot types. Despite challenges from weak semiconductor and consumer electronics sectors since 2021, SCARA robots find demand in emerging industries like lithium-ion battery manufacturing.

The report predicts that sales of components for collaborative robots and SCARA robots will grow rapidly, with expected 5-year CAGRs of 25.1 percent and nine percent. In contrast, the component market for delta robots is forecasted to grow slower, with a CAGR of 6.9 percent from 2022 to 2027.

The markets for force and torque sensors, along with strainwave gearboxes, will benefit from the increased demand for collaborative and SCARA robots. In 2022, 35 percent of force and torque sensor sales came from collaborative robots, expected to rise to 54 percent in 2027. More than 95 percent of collaborative and SCARA robots use strainwave gearboxes, but as they handle larger payloads, cycloidal gearboxes are gaining market share.

Decline forecasted for components pricing

The report explains that in 2022, industrial robot component prices surged globally due to supply chain disruptions, chip shortages, raw material price hikes and inflation. Similar components saw a five to seven percent price increase. However, new, lower-priced suppliers and increased component unit purchases tempered the overall average price rise. Samantha Mou, research analyst at Interact Analysis and author of the report predicts that as inflation eases, competition will quicken price declines from 2023 onward. Key component selling prices are expected to drop by approximately one percent annually starting in 2024. Gearboxes will experience the most significant price decline due to intense competition and rising shipments of strainwave gearboxes, which face considerable pricing pressure.

Growth opportunities

Mou says, “In our research, we noticed increasing interest from component suppliers in the market for non-standard robots manufactured by machine builders (OEMs) and integrated into machines. Unlike the market for traditional ‘off-the-shelf’ robots, the non-standard integrated robot market is seen by component suppliers as an emerging market with great potential and new business opportunities. First, machine OEMs tend to be more flexible in component selection than traditional robot vendors. For example, servo systems for integrated robots are often just generic products from industrial automation suppliers, rather than the custom, robot-specific motors and drives usually required by robot vendors. Second, and as a result, the supply chain for integrated robots is more ‘open’ and competitive than that of standard robots. In the traditional robots’ components market, more than half of the motors and drives used are supplied by robot vendors themselves (we call it a ‘captive’ market), so that component suppliers find it very difficult to gain market share despite the overall large market size.”

The report predicts a quick growth in the currently emerging demand for integrated robots. Mou explains that benefits such as flexible kinematics, machine-integrated centralized control and easier operation make these robots attractive to OEMs.

“Currently, we observe most cases of non-standard robots integrated in packaging machines, although the penetration rate is still minimal. However, the advantages of self-built robots are increasingly coming to the attention of machine builders in a variety of industries, so this market’s growth potential is huge,” explains Mou.

She adds, “The industrial robots and components discussed in the report all refer to the ‘off-the-shelf’ standard robot market because integrated robots currently still present such a small part of the total industrial robot market. However, we will keep paying attention to the development of this market as its share of the traditional market is expected to grow over time.”

Advertisement

- Manufacturing sales, wholesale trade climb in August, as per latest Statistics Canada report

- Endress+Hauser Canada expands smart support coverage with new premium tier